When embarking on construction projects, selecting the right materials is crucial. Hot Dip Pipe emerges as a vital choice due to its numerous benefits. This pipe’s unique galvanizing process enhances durability and resistance to corrosion, making it suitable for various environments.

The strength of Hot Dip Pipe cannot be ignored. It withstands harsh weather conditions and heavy loads. This ensures the longevity of structures. However, some may overlook the initial investment costs, focusing instead on cheaper alternatives. Yet, in the long run, the advantages of Hot Dip Pipe outweigh these initial financial considerations.

Construction professionals may find themselves questioning their material choices. As they weigh options, the nuanced advantages of Hot Dip Pipe become evident. Its reliability in demanding applications speaks volumes. Ultimately, this pipe stands out as a smart investment in quality and sustainability for any construction project.

Hot dip pipe is increasingly popular in construction projects. Its corrosion resistance is a key advantage. According to the National Association of Corrosion Engineers, corrosion costs the U.S. economy over $300 billion annually. Using hot dip pipes can significantly reduce this cost. They are coated in molten zinc, providing a robust shield against rust and degradation. This protection extends the lifespan of the materials, lowering maintenance costs over time.

Another important benefit is strength. Hot dip pipes exhibit superior structural integrity. They can withstand harsh environmental conditions, which is essential in many construction settings. A study from the American Institute of Steel Construction shows that galvanized steel, often used in hot dip pipes, is 3-10 times more durable than untreated steel. Projects can enjoy less downtime due to repairs, enhancing overall productivity.

However, some challenges exist. Hot dip pipes can be heavier than alternatives. This may affect transportation and installation. Additionally, the initial investment can be higher, though savings over time might offset this. We must carefully evaluate the trade-offs before making decisions. Emphasizing both benefits and potential drawbacks leads to well-rounded planning.

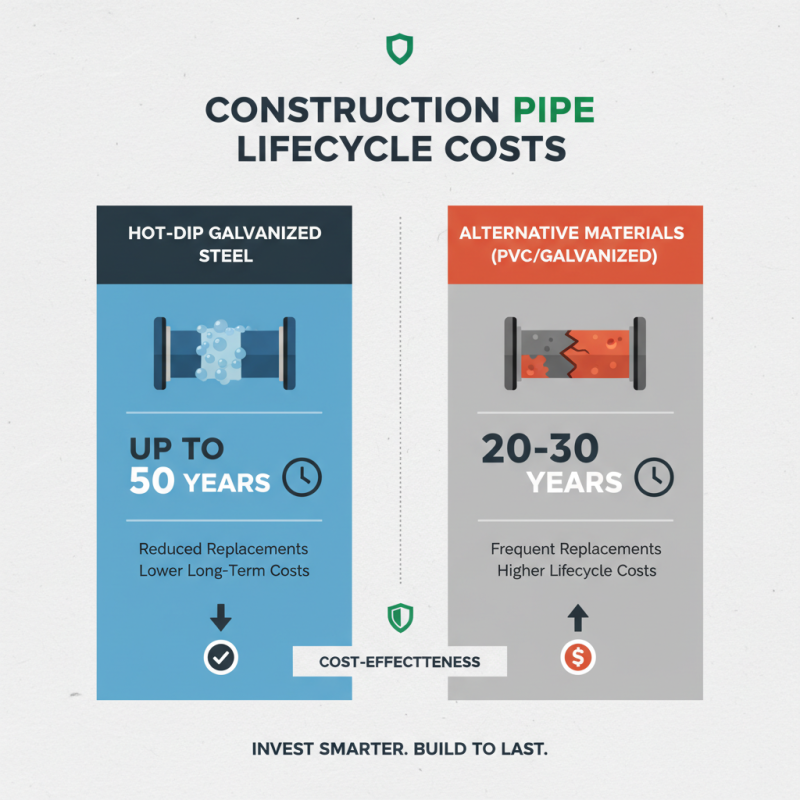

Hot dip pipes are known for their impressive durability and longevity. These pipes undergo a galvanization process that significantly enhances their resistance to corrosion. According to a report from the American Galvanizers Association, hot dip galvanized steel can last over 50 years in outdoor environments. This longevity reduces the need for frequent replacements, ultimately saving on costs.

Corrosion can lead to structural failures. In many projects, traditional steel pipes may degrade within 10 to 20 years. In comparison, hot dip pipes stand strong against harsh weather conditions. This makes them a preferred choice for construction projects. Data from industry experts suggests that using hot dip galvanized pipes can decrease maintenance costs by up to 60%.

However, not all applications may benefit equally from hot dip pipes. In environments with serious chemical exposure, careful consideration is necessary. While they excel in many areas, their ability to withstand specific environments must be evaluated. Even durable materials have limits and processes still require careful reflection. Choosing the right material depends on project specifics and environmental conditions.

Cost-effectiveness is crucial in construction. Hot dip pipes offer a competitive edge. According to data from industry reports, these pipes can last up to 50 years with proper maintenance. This longevity often reduces lifecycle costs significantly. In contrast, alternative materials, like PVC or galvanized pipes, typically need replacing after 20 to 30 years.

Installation costs also play a role. Hot dip pipes generally require less frequent upkeep. A report from a construction analysis firm shows that maintenance costs can be nearly 30% lower over time. It's essential to consider this factor when choosing materials. However, initial purchase prices for hot dip pipes may be higher. This is a common point of contention among builders. Balancing upfront costs with long-term savings can be challenging.

In some scenarios, hot dip pipes might not seem the best option. For instance, in projects with short timelines, alternatives that are easier to install could save time. Yet, the hidden costs of failures in cheaper materials often are overlooked. These failures can lead to delays and unexpected expenses. Ultimately, the value of hot dip pipes shines when considering both immediate and long-term needs.

Hot dip pipes offer several advantages for construction projects, especially in terms of environmental impact. These pipes, coated with zinc, resist corrosion effectively. This resistance prolongs their lifespan, reducing the need for replacements. Fewer replacements mean less waste generated. More importantly, the production process of hot dip pipes is less energy-intensive compared to alternative materials.

Choosing hot dip pipes can also decrease the carbon footprint. They require less maintenance and fewer resources over time, which contributes to sustainability. Workers and communities benefit from reduced exposure to toxic materials when using these pipes. This aspect is crucial as safety becomes a priority in construction practices.

Tips: Always consider the long-term benefits. Opt for products that last longer, even if upfront costs seem higher. Evaluate the recyclability of materials. Hot dip pipes are known for being recyclable, thus minimizing environmental waste. Make informed choices that align with eco-friendly construction practices.

Hot dip pipe offers significant advantages across various industries. In construction, it serves as a reliable choice for structural frameworks. Its corrosion-resistant properties ensure longevity, reducing maintenance costs. For example, piping systems used in water treatment plants often rely on hot dip pipe to withstand harsh conditions.

In the energy sector, hot dip pipes are essential in transporting oil and gas. Their durability allows them to endure extreme temperatures and pressures. This reliability can be crucial during peak demand periods. Yet, challenges remain. Installation must be precisely calibrated to avoid leaks or failures.

Further, the agricultural sector benefits from hot dip pipes for irrigation systems. They provide a strong infrastructure for water transportation. However, improper installation can lead to inefficiencies. Monitoring and maintenance are vital to ensure optimal performance. Hot dip pipes show potential, yet users must remain vigilant.