In the realm of manufacturing and construction, selecting the

appropriate materials is crucial for ensuring

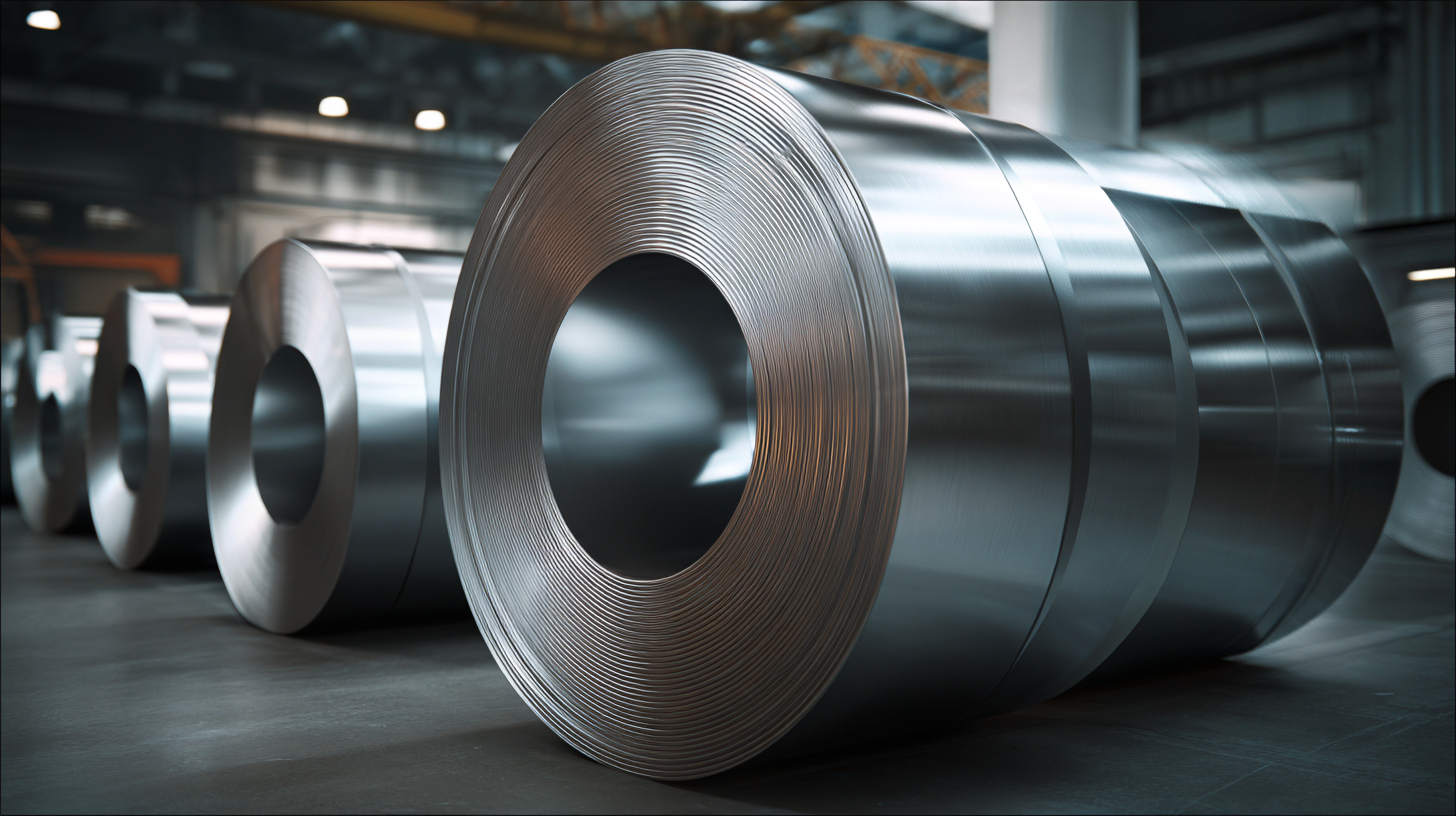

durability and performance. One such material that has gained immense recognition is

Stainless Steel Coil, known for its

corrosion resistance and versatility across various applications.

According to a report by Grand View Research, the global stainless steel market is

projected to reach USD 174.63 billion by 2025, underscoring its significance in

industries ranging from automotive to architecture. Stainless Steel Coil is available in

multiple grades and finishes, making it suitable for a variety of uses including industrial

equipment, food processing, and even architectural facades. Understanding the diverse

characteristics and applications of Stainless Steel Coil is essential for manufacturers

and builders alike, as it not only affects product lifespan but also determines compliance

with global production standards. This blog will explore the characteristics and benefits

of various types of Stainless Steel Coil,

equipping readers with the knowledge needed to select the best option for their specific needs.

In the realm of manufacturing and construction, selecting the

appropriate materials is crucial for ensuring

durability and performance. One such material that has gained immense recognition is

Stainless Steel Coil, known for its

corrosion resistance and versatility across various applications.

According to a report by Grand View Research, the global stainless steel market is

projected to reach USD 174.63 billion by 2025, underscoring its significance in

industries ranging from automotive to architecture. Stainless Steel Coil is available in

multiple grades and finishes, making it suitable for a variety of uses including industrial

equipment, food processing, and even architectural facades. Understanding the diverse

characteristics and applications of Stainless Steel Coil is essential for manufacturers

and builders alike, as it not only affects product lifespan but also determines compliance

with global production standards. This blog will explore the characteristics and benefits

of various types of Stainless Steel Coil,

equipping readers with the knowledge needed to select the best option for their specific needs.

When selecting stainless steel coils, understanding global production standards is essential to ensure quality and performance. These standards are established by recognized organizations such as ASTM, ISO, and EN, which dictate the parameters for chemical composition, mechanical properties, and dimensional tolerances. Adhering to these specifications helps manufacturers maintain consistent quality, minimizing the risk of defects and ensuring that the coils perform optimally in various applications, from automotive to construction.

Moreover, compliant stainless steel coils not only support structural integrity but also contribute to the longevity of the products in which they are used. Variances in production methods and raw materials can significantly impact the end product's durability and corrosion resistance. By scrutinizing the certifications and compliance with international standards, buyers can make informed decisions that align with their project requirements. This deep dive into global production standards not only enhances understanding but also emphasizes the importance of selecting high-quality materials that meet industry benchmarks, ultimately leading to superior outcomes.

Chinese manufacturing plays a pivotal role in shaping global stainless steel standards, as it is one of the largest producers and exporters of stainless steel products. The influence of China can be seen in the way standards are developed and implemented, impacting the quality and specifications of stainless steel coils worldwide. As international markets become more interconnected, understanding these standards is crucial for industries relying on this versatile material.

Tips for selecting the best stainless steel coil involve looking for compliance with established global standards. First, ensure that the manufacturer adheres to recognized quality certifications, which reflect their commitment to high production practices. Additionally, consider the source of raw materials; for instance, the use of high-grade nickel pig iron can significantly enhance the quality of stainless steel. Lastly, stay informed about market trends and prices, as fluctuations can affect both availability and quality of materials.

As the global demand for stainless steel continues to rise, Chinese manufacturers are expected to lead in refining production techniques and setting benchmarks that influence market dynamics. Keeping up with these changes will help businesses make informed decisions, particularly in a landscape where competition and quality are paramount.

When selecting superior stainless steel coils, several key factors come into play that can significantly affect both performance and longevity. One of the foremost considerations is the type of stainless steel used, commonly categorized by grades like 304 and 316. Each grade offers unique properties; for example, 316 stainless steel provides enhanced corrosion resistance, making it suitable for marine environments. Understanding these grades and their applications is crucial for making an informed decision that meets specific project needs.

Another vital aspect to consider is the manufacturing process and production standards of the coils. High-quality stainless steel coils should adhere to international production standards, which ensure consistency, durability, and sustainability. Buyers should look for certifications such as ISO and ASTM, which indicate that the material has been thoroughly tested for quality control. Additionally, the thickness and finish of the coil can influence its performance in various settings, so it’s essential to evaluate these physical characteristics based on the intended application.

When selecting the best stainless steel coil for your needs, understanding the competitive landscape of global manufacturers is crucial. The stainless steel sheet market is experiencing significant growth, projected to expand from $112.43 billion in 2023 to $167.48 billion by 2030. Factors influencing this growth include varying raw material costs and evolving geopolitical conditions, impacting dynamic production capabilities across regions such as Asia, Europe, and the U.S.

To make an informed decision, consider the following tips. First, assess the manufacturer’s compliance with international production standards to ensure product quality and reliability. Second, compare pricing models, keeping in mind the forecasted price trends to optimize your budget allocation for 2025. Additionally, evaluate the supplier’s responsiveness to market fluctuations, as this can affect delivery schedules and inventory management.

By focusing on these elements, you can better navigate the complexities of the global stainless steel coil market and select a manufacturer that aligns with your project's requirements and timelines. Understanding these dynamics will empower you to make strategic decisions that enhance your operational efficiency and product quality.

In the context of stainless steel coil production, sustainability and innovation are not just trends but essential components driving the industry forward. According to a report by the International Stainless Steel Forum (ISSF), the production of stainless steel is becoming increasingly resource-efficient, with a noteworthy reduction of carbon emissions. In fact, the global stainless steel industry aims to reduce carbon emissions by 30% by 2030, highlighting the importance of sustainable practices in manufacturing processes.

Innovative technologies are integral to this evolution. The implementation of advanced recycling techniques has enabled manufacturers to source up to 90% of their raw materials from recycled stainless steel scrap. This not only conserves natural resources but also significantly cuts down waste, as stainless steel is infinitely recyclable without losing its quality. Furthermore, stainless steel production is benefiting from innovations in energy efficiency, with some companies adopting renewable energy sources, which contribute to a greener production cycle. As these advancements continue to reshape the industry, stakeholders must prioritize understanding these global production standards to select the most sustainable and innovative stainless steel coils available.