Steel plates play a crucial role in construction. They offer strength, durability, and versatility. Various types of steel plates are used for different applications. Understanding these types helps in making informed choices.

Common steel plates include carbon steel, stainless steel, and alloy steel. Carbon steel plates are widely used due to their affordability and strength. Stainless steel plates resist corrosion, making them ideal for harsh environments. Alloy steel plates, on the other hand, provide enhanced mechanical properties for specialized needs.

Choosing the right steel plate can be challenging. Factors like thickness, size, and type affect performance. Some projects may not require the best material, leading to overspending. Others may underestimate the importance of quality, compromising safety. It's essential to strike a balance.

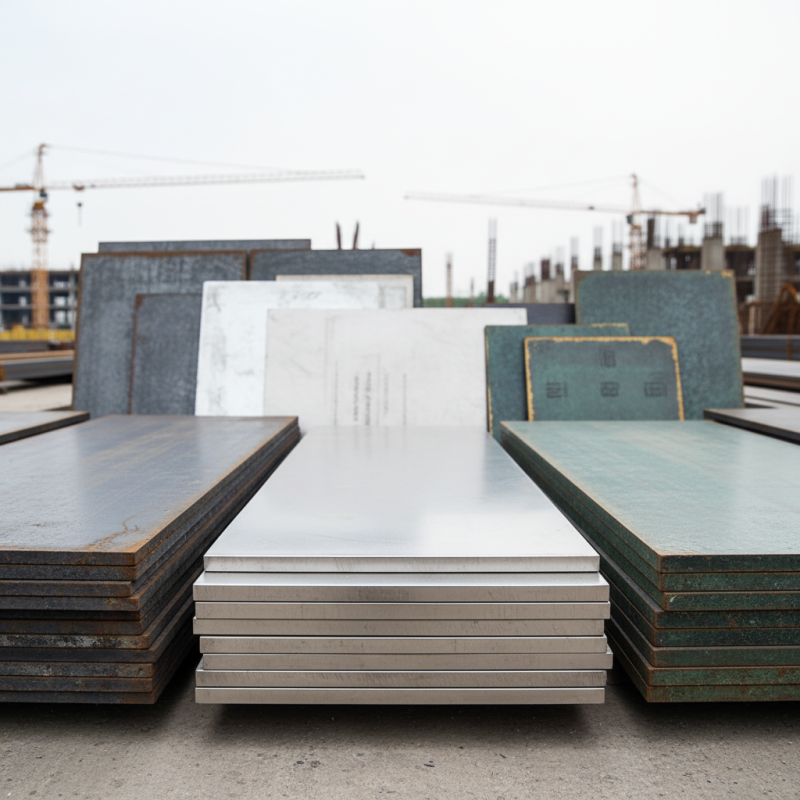

Steel plates play a crucial role in construction. They provide strength and durability for various structures. Different types of steel plates have unique properties. Here are some commonly used types.

Structural steel plates are essential for buildings and bridges. They are designed to support heavy loads. Another type is carbon steel plates, known for their versatility. These plates can be used in many applications, from pipelines to car parts. Stainless steel plates resist corrosion. They are ideal for environments exposed to moisture.

There are limitations to each type of plate. Structural plates can be heavy. This may increase transportation costs. Carbon steel plates may rust without protective coating. Stainless steel, while durable, can be expensive. Each choice must consider specific project needs. Balancing cost and performance is vital.

This bar chart illustrates the thickness of various types of steel plates commonly used in construction. The thickness values indicate the typical dimensions used in structural applications, showcasing the differences between mild steel, high-strength steel, stainless steel, wear-resistant steel, and tool steel plates.

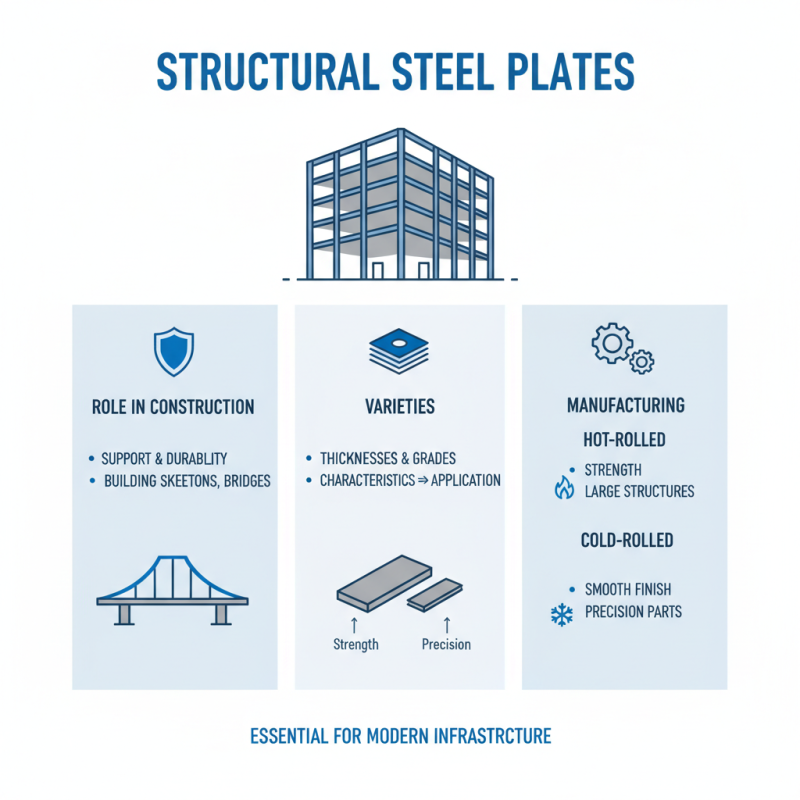

Structural steel plates are crucial in construction. They provide support and durability to various structures. These plates come in different thicknesses and grades. Their characteristics determine their application. Typically, they are manufactured through hot-rolled or cold-rolled processes. Hot-rolled steel is known for strength. Cold-rolled steel offers better surface finish and precision.

When selecting steel plates, consider their tensile strength and yield point. The thickness can affect the bending and welding performance. If the plate is too thick, it may be challenging to cut. Too thin, and it may not provide enough support. Always analyze the load requirements before making a choice.

Tips: Ensure that you understand the specifications required for your project. Sometimes, a standard plate may not fit your needs. Custom plates might be the solution, but they can be costly and time-consuming. It's essential to balance cost with structural integrity. Reach out to professionals when in doubt. Remember, an informed choice can prevent costly mistakes down the road.

Steel plates come in various types, each serving distinct roles in construction. For instance, structural steel plates are commonly utilized in beams and columns. According to the American Institute of Steel Construction (AISC), around 60% of new buildings use steel framing. This highlights the importance of quality steel plates in modern architecture.

Another significant type is marine-grade steel plates. These are often applied in coastal construction and shipbuilding. The corrosion resistance of these plates extends the lifespan of structures exposed to harsh environments. A study by ASTM International found that marine-grade steel can outperform standard steel by up to 50% in resilience to saltwater corrosion.

Then there's boiler steel plate, vital in energy production. These plates withstand high pressure and temperature. Reports indicate that the global demand for boiler steel plates is projected to reach 1.5 million tons by 2025. However, navigating safety standards and material quality can pose challenges for manufacturers. The industry must consistently evaluate and adapt to these evolving requirements.

Steel plates are essential in construction. Different types have unique advantages and disadvantages. For example, carbon steel plates are widely used. They are durable and cost-effective. However, they can be prone to rust without proper treatment.

Stainless steel plates offer excellent corrosion resistance. They can withstand harsh environmental conditions. The downside? They are more expensive. Some projects may not justify the higher cost. Aluminum plates, on the other hand, are lightweight and easy to handle. But their strength is lower than steel, limiting their use in heavy applications.

Each material presents its challenges. The selection often depends on specific project needs and budget. Wielding heavy plates can be tough, sometimes causing errors. Proper training and planning are crucial. Understanding these pros and cons can lead to better decisions in construction projects.

Construction steel plates adhere to various standards and specifications, ensuring quality and performance. The American Society for Testing and Materials (ASTM) outlines these standards. ASTM A36 is among the most common specifications. It is known for its excellent weldability and machinability. This steel plate has a yield strength of 36 ksi, suitable for many construction applications.

Another notable specification is ASTM A572. This steel allows for higher strength at a lower weight. ASTM A572 grades include 42, 50, and 55, making them versatile for structural components. The tensile strength ranges from 65 to 80 ksi, ensuring durability under various loads. Builders appreciate the balance it offers between strength and weight, making it useful in construction projects.

Tips: Always check for certifications when purchasing steel plates. Use plates that meet the required specifications for your project. It prevents potential structural failures. Remember that not all steel meets high-grade standards. Look for options with proper testing reports. Keep in mind that ignoring standards can lead to costly mistakes.