Galvanized plates play a crucial role in various industries, particularly in construction and manufacturing. This material is coated with zinc to prevent corrosion. According to a recent industry report, the global galvanized steel market is expected to reach $150 billion by 2026. This growth highlights the increasing demand for durable and cost-effective materials.

In construction, galvanized plates are commonly used for roofing, siding, and structural supports. Their resistance to rust makes them ideal for long-lasting infrastructures. Many companies prefer them over untreated steel, but there are challenges. The production process may lead to inconsistencies in coating thickness, which can impact performance.

Moreover, while galvanized plates provide numerous benefits, they are not without their drawbacks. Some argue that the zinc coating can wear off over time, which can compromise the material’s integrity. It's essential for industries to weigh these factors, ensuring that they choose the right applications for galvanized plates. The ongoing debate surrounding their long-term efficacy is worth noting as the market evolves.

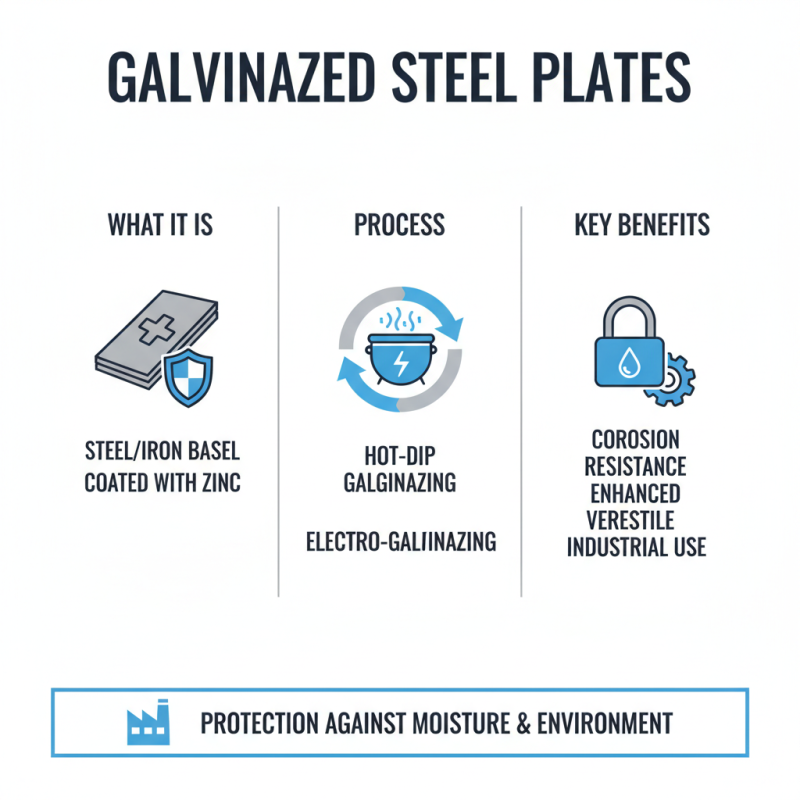

Galvanization is a process that protects metals from corrosion. It involves coating steel or iron with a layer of zinc. This zinc layer acts as a barrier against moisture and oxygen, which are the main culprits behind rust. The galvanization process can be done through hot-dipping or electroplating. Each method has its unique advantages and applications.

When it comes to industry, galvanized plates are prevalent. They are found in construction, automotive manufacturing, and even household appliances. Galvanized plates resist harsh environments, which make them ideal for outdoor use. They also require less maintenance compared to non-galvanized metal.

Tips: When choosing galvanized materials, look for thickness and coating type. A thicker coating often provides better rust protection. It’s vital to consider the environment where the plates will be used. Different settings may call for specific types of galvanization.

While galvanization is effective, it is not foolproof. Over time, even galvanized coatings can degrade. Regular inspections can help identify any wear and tear. Understanding the limitations of galvanization is crucial for optimal performance in industrial applications.

This chart illustrates the various applications of galvanized plates across several industries, highlighting the importance of galvanization in enhancing durability and corrosion resistance.

Galvanized plates are coated with zinc to prevent corrosion. This process enhances their durability, making them suitable for various industrial applications. The composition primarily involves steel or iron, coated by a hot-dip or electrogalvanizing method. The zinc coating creates a barrier, shielding the metal from moisture and environmental elements.

According to industry reports, galvanized plates possess a typical coating thickness ranging from 50 to 200 microns. This thickness significantly extends the material's lifespan. However, not all galvanized plates are created equal. Variations exist in coating methods, which impact performance. Some manufacturers may cut corners, leading to inadequate coverage.

Galvanized plates are commonly used in construction and automotive sectors. For example, they are utilized in roofing systems, handrails, and structural supports. A study observed that using galvanized steel in construction reduces maintenance costs by up to 30%. Nonetheless, it's crucial to choose high-quality materials. Thin coatings may lack the necessary protection, resulting in premature rusting. This emphasizes the need for responsible sourcing in industrial applications.

Galvanized plates are metal sheets coated with a layer of zinc for protection against corrosion. These plates are widely used across various industries. In construction, they serve as structural components. A report shows that the construction industry accounts for over 40% of zinc consumption globally. The durability of galvanized plates makes them ideal for both indoor and outdoor applications.

In the automotive industry, galvanized plates play a crucial role. They are used for chassis and body components due to their corrosion resistance. This is especially important in cars exposed to harsh weather conditions. Data indicates that nearly 75% of new vehicles utilize galvanized metal to enhance longevity and safety.

Galvanized plates are also common in the manufacturing of appliances and furniture. They provide a sturdy base for products exposed to moisture. However, despite their benefits, the process of galvanization can introduce environmental concerns. The discharge of zinc into water sources during production needs careful management. Balancing these advantages and challenges is crucial for sustainable industry practices.

Galvanized plates are widely recognized for their durability and resistance to corrosion. These plates are coated with a layer of zinc, which acts as a protective barrier. This coating helps prevent rust, extending the plate's lifespan significantly. Industries depend on galvanized plates for various applications, such as construction, automotive, and agriculture.

One key advantage of galvanized plates is their cost-effectiveness. While initial costs may be higher than some other materials, the long-term savings on maintenance are substantial. For instance, buildings made with galvanized steel require less frequent repairs. Additionally, their lightweight nature allows for easier transport and installation. However, the quality of the zinc coating can vary. This inconsistency may lead to some plates failing prematurely, which should be considered when making a selection.

Another notable benefit is their versatility. Galvanized plates can be easily shaped and welded for specific projects and retain their aesthetic appeal over time. Yet, the need for proper handling is crucial. Scratches during installation can compromise the protective layer. It's essential to be mindful of these factors to ensure optimal performance in various industrial applications.

Galvanized plates are known for their resistance to corrosion. However, regular maintenance is crucial to ensuring their longevity in industrial settings. Over time, exposure to moisture and chemicals can compromise their protective coating. Small scratches or dents can lead to rusting, creating larger issues if not addressed promptly. Inspecting and repairing these imperfections can significantly extend the lifespan of galvanized products.

Routine cleaning is another aspect of maintenance. Dust and grime can accumulate and trap moisture against the surface. This can accelerate degradation. Using a mild detergent and gentle scrub can help maintain the integrity of the galvanization. Additionally, ensuring proper drainage in areas where these plates are used can minimize standing water, reducing the risk of corrosion.

Despite their durability, no material is impervious to wear. In some cases, the galvanization may not cover edges or cut areas effectively. These spots are particularly vulnerable. Traditional practices recommend applying touch-up paint or additional coatings to these areas. The goal is to create a continuous layer of protection. It’s a process that requires diligence and ongoing effort.

| Dimension | Value | Notes |

|---|---|---|

| Thickness | 0.5 mm to 5 mm | Common thickness for various applications |

| Common Sizes | 1000 mm x 2000 mm | Standard sheet size for industrial use |

| Coating Weight | Z120 to Z450 g/m² | Indicates corrosion resistance level |

| Uses | Construction, Automotive, Electrical | Widely used in diverse industrial applications |

| Longevity | 15 to 50 years | Depending on environment and maintenance |