Galvalume Steel Coil has emerged as a vital material in the modern construction industry, combining the benefits of durability, corrosion resistance, and aesthetic appeal. This unique coating of aluminum and zinc applied to steel enhances its lifespan, making it an ideal choice for various applications, including roofing, siding, and structural components. The significance of Galvalume Steel Coil lies not only in its physical properties but also in its cost-effectiveness, which contributes to the overall efficiency of construction projects.

As the construction sector continues to evolve, the demand for materials that meet both functional and environmental requirements has increased. Galvalume Steel Coil stands out as a preferred option due to its ability to withstand harsh weather conditions while requiring minimal maintenance. Its reflective surface also contributes to energy efficiency by reducing heat absorption, which is a crucial factor in sustainable building practices. In this context, understanding what Galvalume Steel Coil is and its importance offers valuable insights for builders, architects, and engineers looking to enhance the longevity and performance of their projects.

Galvalume steel coil is a versatile and durable material widely used in the construction industry. It is primarily composed of steel that is coated with a mixture of aluminum and zinc, providing exceptional resistance to corrosion. The aluminum forms a protective barrier that prevents rusting, while the zinc offers additional protection through a process known as galvanic action. This unique combination not only enhances the longevity of the steel but also ensures that it can withstand harsh environmental conditions, making it an ideal choice for roofing and siding applications.

The composition of Galvalume steel coil typically consists of about 55% aluminum, 43.4% zinc, and a small percentage of silicon. This specific ratio contributes to its impressive performance characteristics, such as increased reflectivity and improved thermal efficiency. The coating process involves hot-dipping the steel in the molten mixture, creating a strong bond between the steel and the protective layer. As a result, Galvalume steel coil not only offers structural integrity but also aesthetic appeal, as it can be manufactured in various finishes and colors, catering to diverse architectural designs.

This chart illustrates the increasing usage of Galvalume Steel Coil in various construction applications over the last few years. The data demonstrates its growing popularity due to excellent corrosion resistance and durability.

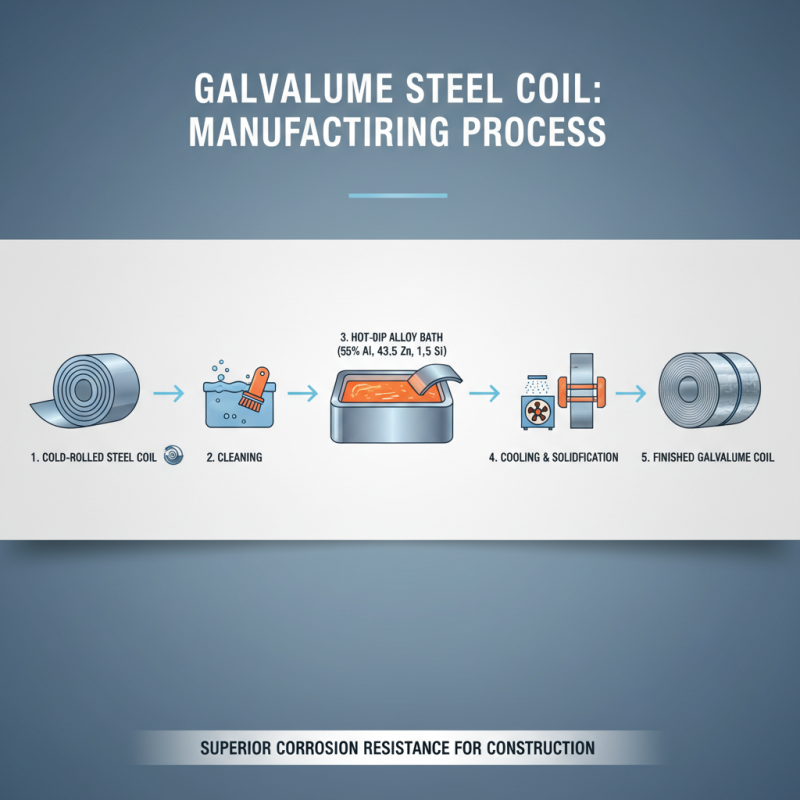

The manufacturing process of Galvalume steel coil is a critical aspect that contributes to its popularity in the construction industry. Galvalume, a steel product coated with an alloy of aluminum and zinc, is produced using a continuous hot-dip process. In this method, cold-rolled steel coils are first cleaned and then passed through a molten bath containing the aluminum-zinc alloy, which typically comprises 55% aluminum, 43.5% zinc, and 1.5% silicon. This coating provides superior corrosion resistance compared to traditional galvanized steel, making it an ideal choice for numerous construction applications.

After the coating process, Galvalume coils undergo a series of mechanical and thermal treatments to achieve desired properties such as strength and flexibility. According to a report by the Steel Research Institute, the mechanical properties of Galvalume steel coils show a yield strength range of 220-350 MPa, making them suitable for structural applications. Furthermore, the coating's reflective properties significantly enhance energy efficiency in buildings, contributing to lower heating and cooling costs. As a result, Galvalume steel coil has become a preferred material in roofing, siding, and other architectural elements, underscoring its importance in modern construction practices.

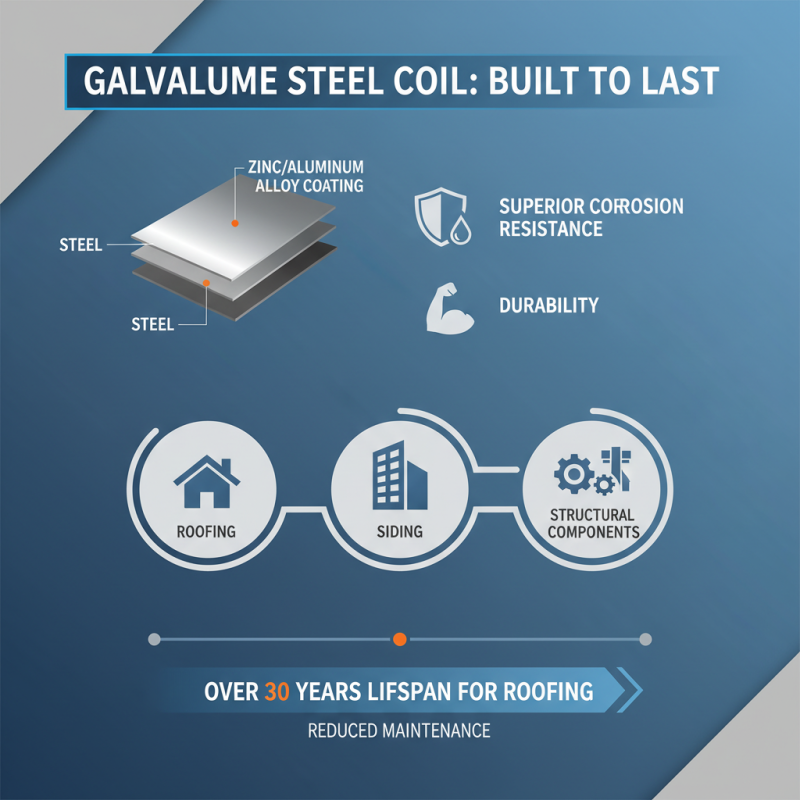

Galvalume steel coil is a galvanized steel product coated with a blend of aluminum and zinc, providing enhanced durability and corrosion resistance. This unique structure combines the properties of both metals, resulting in a protective layer that can withstand harsh weather conditions. According to industry reports, Galvalume exhibits a remarkable lifespan of over 25 years without significant corrosion, making it an invaluable choice in construction, particularly for roofing and siding applications. Its reflective surface also contributes to energy efficiency, lowering cooling costs in buildings by reflecting sunlight.

One of the key benefits of Galvalume steel coil is its excellent formability and workability. It can be easily fabricated into various shapes, which significantly reduces labor costs during construction. Furthermore, the coating process improves adhesion for paints and other finishes, ensuring a high-quality aesthetic that maintains its appeal over time. Research indicates that structures utilizing Galvalume can reduce maintenance costs by up to 50% compared to traditional steel, making it an economically viable option for builders and architects. The balance of strength, longevity, and cost-effectiveness underscores the importance of Galvalume steel coil in today’s construction landscape.

| Property | Description |

|---|---|

| Corrosion Resistance | Galvalume steel coils offer excellent corrosion resistance due to the zinc-aluminum alloy coating. |

| Durability | Highly durable and can withstand harsh weather conditions, making it ideal for roofing and siding materials. |

| Heat Reflectivity | Galvalume steel has higher heat reflectivity, contributing to energy efficiency in buildings. |

| Aesthetic Appeal | Available in various finishes and colors, which enhance the visual appeal of the structures. |

| Low Maintenance | Requires minimal maintenance, reducing long-term costs for property owners. |

| Recyclability | Made from recyclable materials, contributing to sustainable construction practices. |

Galvalume steel coil is a vital material in the construction industry due to its superior corrosion resistance and durability. Its unique composition, which includes a coating of aluminum and zinc, makes it an ideal choice for a wide range of structural applications. Among its many uses, Galvalume steel coil is commonly employed in roofing, siding, and the fabrication of various structural components. According to industry reports, buildings utilizing Galvalume roofing systems can enjoy a lifespan of over 30 years, significantly reducing maintenance costs.

Additionally, the energy efficiency of Galvalume products is noteworthy. The reflective properties of the aluminum coating help in reducing heat absorption, which can lead to lower energy costs in climate-controlled environments. A study from the Metal Construction Association indicates that utilizing reflective roofing materials can save up to 20% on cooling costs in hot climates, making Galvalume an economically sensible option for modern construction projects.

Tips: When selecting materials for construction, always consider local climate conditions and energy efficiency ratings. For roofing and siding in regions prone to severe weather, Galvalume's resilience becomes a critical factor in ensuring long-term performance and safety. Furthermore, ensure proper installation techniques to maximize the lifespan and benefits of Galvalume products.

Galvalume steel coil has gained recognition for its significant environmental and economic advantages in construction. Made by coating steel with a blend of aluminum and zinc, it offers exceptional corrosion resistance and durability, which extends the lifespan of structural components. This longevity contributes to reduced material waste, lower replacement costs, and minimized environmental impact, aligning with sustainable building practices. By utilizing Galvalume, construction projects can reduce their carbon footprint, as fewer resources are expended in manufacturing and disposing of traditional materials.

Economically, Galvalume steel coil is an efficient choice for builders and developers. Its lightweight nature allows for easier handling and installation, resulting in decreased labor costs and shorter construction timelines. Additionally, the reflective properties of Galvalume enhance energy efficiency in buildings, as it can reduce heat absorption, leading to lower cooling costs. The combination of these factors makes Galvalume not only a practical option but also an economically viable choice that supports the growth of sustainable construction. These benefits underscore its role in modern architecture and infrastructure development, promoting both environmental stewardship and economic growth within the industry.