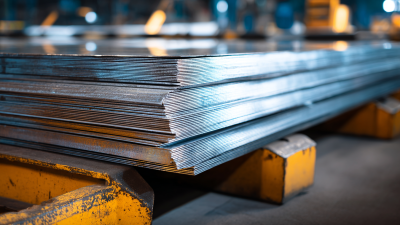

The modern manufacturing landscape increasingly demands materials that balance performance, cost-effectiveness, and sustainability. Stainless Steel Coil has long been a staple due to its corrosion resistance and strength; however, challenges such as price volatility and environmental impact have prompted industries to seek innovative alternatives. According to a recent market analysis by Smithers, the global stainless steel market is projected to reach $130 billion by 2024, yet the rising costs of nickel and other key alloying elements are pushing manufacturers to explore new materials. Additionally, a study from the World Economic Forum highlights that innovations in advanced polymers and composites could potentially reduce production costs by 20% while maintaining desired mechanical properties. As we delve into the exploration of these alternatives, it is crucial to assess not only their technical capabilities but also their environmental footprint and economic viability in comparison to traditional Stainless Steel Coil.

In the realm of modern manufacturing, the exploration of innovative materials beyond traditional options like stainless steel coil is gaining momentum. As industries strive for enhanced performance, sustainability has become a central theme. This aligns with recent initiatives such as Yunnan Province's "14th Five-Year Plan" for high-quality development in manufacturing, which emphasizes the construction of a green manufacturing framework. The integration of eco-friendly materials not only meets environmental standards but also fosters efficiency and durability in product design.

Alternative materials such as advanced composites, aluminum alloys, and bio-based plastics are emerging as viable substitutes, offering unique benefits in terms of weight reduction and corrosion resistance. Manufacturers are increasingly adopting these innovative options to reduce their carbon footprint while maintaining high-quality production. Additionally, the emphasis on circular economy principles encourages the development of materials that can be recycled or repurposed, thereby minimizing waste and promoting sustainability in the supply chain. As we push the boundaries of what’s possible in manufacturing, the transition towards these innovative materials is not just a trend but a necessary evolution in the industry.

Aluminum alloys are emerging as promising alternatives to stainless steel, particularly in modern manufacturing applications where weight reduction and performance enhancement are crucial. Recent research highlights advancements in high-temperature aluminum alloys that provide improved mechanical properties, making them suitable for various demanding environments. Specifically, cost-effective aluminum alloys showcase enhanced performance, which broadens their appeal for industries ranging from aerospace to automotive.

Moreover, the exploration of aluminum alloys is complemented by developments in manufacturing techniques such as multi-wire arc additive manufacturing, which enables the layer-by-layer construction of complex components with superior material properties. The ability to optimize the mechanical performance of high-strength aluminum alloys through precise manufacturing technologies paves the way for innovative applications, ultimately challenging conventional stainless steel norms. This intersection of material science and advanced manufacturing techniques may redefine design standards and production efficiencies within multiple sectors.

| Property | Stainless Steel | Aluminum Alloy | Performance Evaluation |

|---|---|---|---|

| Density (g/cm³) | 8.0 | 2.7 | Aluminum is significantly lighter, ideal for weight-sensitive applications. |

| Tensile Strength (MPa) | 520 | 300 | Stainless steel offers greater tensile strength, making it preferable in high-stress applications. |

| Corrosion Resistance | Excellent | Good (with specific coatings) | Stainless steel exhibits superior corrosion resistance, important in harsh environments. |

| Thermal Conductivity (W/m·K) | 16 | 230 | Aluminum alloys perform much better in thermal conductivity, beneficial for heat exchangers. |

| Cost ($/kg) | 3.50 | 2.50 | Aluminum alloys are generally more cost-effective, enabling budget-friendly designs. |

The rise of carbon fiber composites in modern manufacturing applications marks a significant shift in materials science, offering unparalleled advantages over traditional metals, including stainless steel. As industries increasingly require lightweight yet durable materials, carbon fiber emerges as a compelling alternative. Its remarkable strength-to-weight ratio allows manufacturers to create products that maintain structural integrity while reducing overall mass. This is particularly advantageous in sectors such as aerospace, automotive, and sporting goods, where every ounce counts toward enhancing performance and fuel efficiency.

Furthermore, the versatility of carbon fiber composites enables a wide range of design possibilities that stainless steel simply cannot match. Manufacturers can mold these composites into complex shapes, allowing for greater innovation in product development. This flexibility fosters creativity and drives advancements in engineering solutions, contributing to more sustainable manufacturing practices. As companies seek to reduce their carbon footprint and improve efficiency, the adoption of carbon fiber composites represents a forward-thinking approach that aligns with modern manufacturing demands.

In modern manufacturing, the shift towards cost-effective materials has led to an exploration of polymer coatings as viable alternatives to traditional stainless steel coil. According to a report by MarketsandMarkets, the global polymer coatings market is projected to reach USD 43.6 billion by 2025, indicating a robust growth driven by their cost efficiency and versatility. Unlike stainless steel, which involves both material costs and extensive processing, polymer coatings can significantly reduce production costs, estimated to be up to 25% lower, while also offering enhanced properties such as resistance to corrosion and abrasion.

Furthermore, the longevity of polymer coatings compared to stainless steel coil plays a crucial role in their cost-effectiveness. A study from the Technical Association of the Pulp and Paper Industry (TAPPI) indicates that polymer coatings can extend the life of components by up to 50%, resulting in lower maintenance and replacement expenses. This durability, along with their lighter weight and ease of application, positions polymer coatings as an innovative alternative for manufacturers looking to optimize their bottom line without compromising on performance or quality.

The shift towards sustainability in manufacturing has prompted a demand for eco-friendly alternatives to traditional materials like stainless steel coil. According to a report by Smithers, the global demand for green materials in manufacturing is expected to reach $50 billion by 2025. Innovations in materials science have led to the development of bio-based composites, recycled aluminum, and thermoplastic polymers, which not only reduce the carbon footprint but also enhance product functionality. For instance, studies indicate that bio-composites made from agricultural waste can offer strength similar to that of stainless steel while being significantly lighter and more sustainable.

In addition, the use of recycled metals in manufacturing processes has gained traction. The Aluminum Association reports that recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials. This energy efficiency leads to lower greenhouse gas emissions, making recycled aluminum a compelling alternative to stainless steel coil. As manufacturers increasingly adopt these sustainable options, they are not only enhancing their environmental profiles but also creating opportunities for innovation and cost savings in their supply chains.

This chart illustrates the percentage usage of various eco-friendly alternatives to stainless steel coil in modern manufacturing. Aluminum leads with 35%, showcasing its popularity, followed by carbon steel and titanium with 25% and 20% respectively. This data highlights the growing trend towards sustainable materials in manufacturing processes.