Choosing the right galvanized plate is vital for numerous projects. Galvanized plates provide durability, corrosion resistance, and strength. According to a report by the Zinc Development Association, the global demand for galvanized steel is projected to reach over 200 million tons by 2025. This figure highlights the increasing reliance on galvanized products across various industries.

When selecting galvanized plates, several factors must be considered. Thickness, coating type, and application context are essential details. For instance, the American Galvanizers Association reports that a thicker coating can extend the lifespan of galvanized steel in harsher environments. However, not all applications require heavy coating, which can add unnecessary costs.

Many buyers overlook important nuances. Understanding the difference between mechanical and hot-dip galvanizing can impact performance and pricing. While both methods offer corrosion protection, each has its own cost implications. It's crucial to reflect on your project needs before making a choice. Careful consideration will lead to better outcomes.

Galvanized plates are steel plates coated with a layer of zinc. This protective coating increases durability and resistance to corrosion. The applications of galvanized plates are diverse. They are commonly used in construction, automotive, and agriculture sectors. For instance, a report from the American Galvanizers Association highlights that over 90% of galvanized steel is used in structural applications.

When choosing galvanized plates, consider their thickness and the type of zinc coating. Thicker plates provide more durability but may cost more. Look for zinc coatings that meet ASTM standards for better quality assurance. These details can significantly impact the longevity and performance of the material. Remember, not all galvanized plates are created equal.

Here are some tips for selection. First, assess the environment where the plates will be used. Harsh conditions may require thicker coatings. Second, evaluate the plate's intended application. Specific needs may call for specialized coatings. Lastly, seek out expert recommendations to ensure you make an informed choice. Attention to detail can prevent costly mistakes in the long run. Thoughtful evaluation leads to better choices.

When selecting galvanized plates, several key factors come into play. One important aspect is understanding the coating's thickness. Thicker coatings offer better corrosion resistance. However, they may also add to the plate’s weight and cost. This balance can be tricky.

Another factor to consider is the environment in which the plates will be used. Humid or coastal areas can accelerate corrosion. In such cases, you may need to choose plates with enhanced protective treatments. Think about the length of time you need them to last.

Lastly, examine the intended application of the galvanized plates. Are they being used in construction or manufacturing? The required strength and durability might differ in these scenarios. Sometimes, the hardest choice is not about price but about future performance. Always ask yourself: Will this choice meet my long-term needs? This reflection is crucial for making the right selection.

This bar chart illustrates the key factors to consider when selecting galvanized plates, showcasing the importance of various criteria in making a decision.

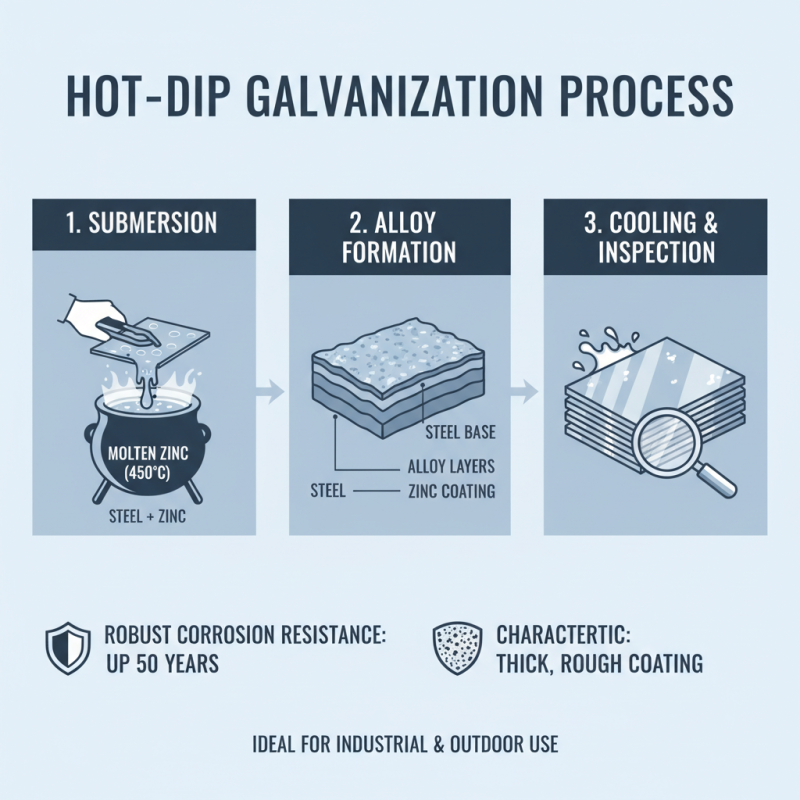

When selecting galvanized plates, understanding the different types of galvanization processes is crucial. Hot-dip galvanization is a popular method. In this process, steel plates are submerged in molten zinc. Reports show that this method creates a thick, robust coating. It can withstand corrosion for up to 50 years. However, the surface may have a rough texture, which may not suit all aesthetic needs.

Electro-galvanization is another option. It involves electrical currents to deposit zinc onto the steel. This creates a thinner, smoother finish. While it offers a good level of protection, its lifespan is around 10 to 20 years. This duration may not be adequate in harsh environments. Some projects may require more durable solutions.

Looking at these processes highlights a gap in awareness. Many choose based on cost alone, ignoring long-term benefits. For instance, hot-dip galvanization might be pricier upfront but saves money in maintenance. Understanding these differences ensures better decisions.

When evaluating the corrosion resistance of galvanized plates, it's essential to understand how the galvanization process works. This technique involves coating steel or iron with zinc to prevent rust. The zinc layer acts as a barrier, protecting the underlying metal. According to industry reports, galvanized plates can last 50 years or more in favorable conditions.

Tip: Always check the thickness of the zinc coating. A heavier coating generally means better protection. The American Galvanizers Association states that a typical coating thickness ranges from 5 to 20 microns. This can greatly influence the plate's lifespan in corrosive environments.

Another factor is the environmental conditions where the plates will be used. Moisture, temperature, and exposure to chemicals can all affect corrosion rates. For example, coastal areas may accelerate corrosion due to salt exposure. It's crucial to assess your specific environment before purchasing galvanized plates.

Tip: Conduct a surface inspection for any pre-existing blemishes. Even small imperfections can lead to early corrosion. Small steps taken now can extend the life of your galvanized plates.

When budgeting for galvanized plates, understanding the cost dynamics is crucial. On average, the price of galvanized steel can range from $0.45 to $2 per pound, depending on thickness and coating quality. Factors such as market demand and global steel prices impact these costs significantly. The recent report by the Steel Market Update noted a 5% price increase in galvanized sheets due to rising raw material costs.

Consider the additional expenses linked to shipping and handling. Transport costs vary widely based on location. For instance, if you're sourcing plates from overseas, you might incur hefty freight charges. According to industry insights, neglecting these costs could lead to an unrealistic budget model. Having a cushion for unexpected price fluctuations is essential.

Quality does play a role in pricing. Lower-cost galvanized plates may save money initially, but they might rust or corrode faster, leading to higher replacement costs. According to a study by the International Zinc Association, a high-quality galvanized plate can last over 50 years with proper maintenance. Weighing initial costs against long-term value is vital for effective budgeting. Always reassess your choices to ensure you’re not compromising on quality for a lower price.