Choosing the right stainless steel pipe for your project needs is a critical decision that can significantly impact the overall success and longevity of your applications. Stainless steel pipes are renowned for their durability, corrosion resistance, and aesthetic appeal, making them a popular choice across various industries, including construction, manufacturing, and plumbing. However, with a multitude of options available in terms of size, grade, and finish, selecting the appropriate stainless steel pipe can seem daunting.

Understanding the specific requirements of your project is essential in navigating the diverse world of stainless steel pipes. Factors such as pressure tolerance, temperature conditions, and environmental exposure all play a vital role in determining which type of stainless steel pipe will be most suitable for your needs. Additionally, familiarity with different standards and specifications can equip you with the knowledge necessary to make informed choices, ensuring that your materials meet industry regulations and performance expectations.

In this guide, we will explore the key considerations for selecting the right stainless steel pipe, highlighting the characteristics that define their performance and suitability for various applications. By gaining insight into the properties and applications of stainless steel pipes, you will be better prepared to make decisions that enhance the effectiveness and safety of your projects.

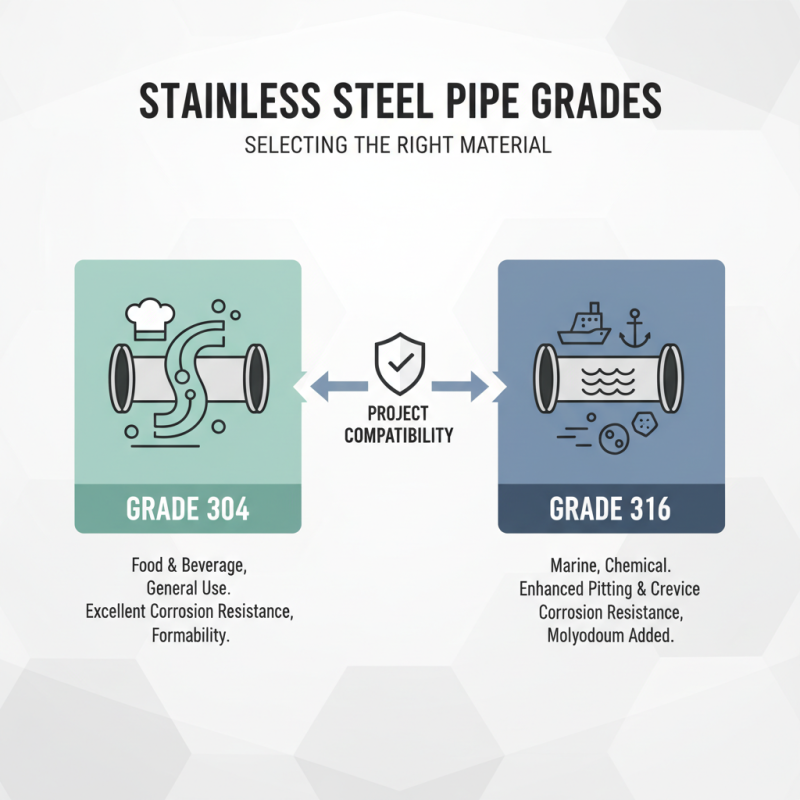

When selecting stainless steel pipes for your project, several key factors must be considered to ensure you make the right choice. Firstly, assess the environment where the piping will be installed. Different grades of stainless steel, such as 304 and 316, provide varying levels of corrosion resistance. For example, 316 stainless steel is often preferred for marine or highly corrosive environments due to its enhanced resistance to rust and pitting. Understanding the specific conditions your pipes will face is essential to selecting the appropriate grade.

Additionally, consider the pipe size and wall thickness required for your project. This will depend on the fluid type, pressure, and the application itself. Larger diameters are necessary for high-volume applications, while thinner walls may suffice for lower pressure systems. It's also critical to evaluate the manufacturing process of the pipes. Whether you need seamless or welded pipes can influence both performance and cost. Evaluating these factors meticulously can help ensure that your selection of stainless steel pipes aligns with the functionality and longevity needed for your project.

When selecting stainless steel pipes for your project, understanding the different grades is crucial for ensuring compatibility with your specific requirements. Stainless steel comes in various grades, each with distinct properties that make them suitable for various applications. The most common grades include 304 and 316, with 304 being widely used for its excellent corrosion resistance and formability, making it ideal for food and beverage processing. In contrast, 316 provides enhanced resistance to pitting and crevice corrosion, particularly in marine environments, due to the addition of molybdenum.

Additionally, there are specialized grades such as 321, which are designed for high-temperature applications, and duplex stainless steels, which offer high strength and corrosion resistance, making them suitable for demanding environments. When choosing a stainless steel pipe, it is essential to consider factors such as the environment it will be exposed to, mechanical requirements, and any relevant regulatory standards. By understanding these different grades and their properties, you can make informed decisions that will lead to a successful project outcome.

When embarking on a project that requires stainless steel pipes, it's crucial to pinpoint the specific requirements that will guide your selection process. Begin by assessing the environment in which the pipes will be used. Factors such as temperature, pressure, and exposure to corrosive substances can drastically influence the type of stainless steel needed. For instance, a project in a marine setting may require pipes that can withstand higher levels of salt corrosion, necessitating the use of higher-grade stainless steels like 316, which is more resistant to such conditions.

Another important consideration is the dimensional requirements, including the diameter and wall thickness of the pipes. The desired flow rate and the physical space available for installation will inform these specifications. Additionally, the intended application—whether it be for plumbing, structural support, or chemical transport—will dictate other characteristics, such as compliance with relevant regulations and safety standards. By clearly defining these project needs upfront, you can ensure that the selected stainless steel pipes not only perform effectively but also align with long-term project objectives.

When evaluating the right stainless steel pipe for your project, two critical factors to consider are the pipe diameter and wall thickness. The diameter of the pipe impacts the flow rate and pressure drop within the system. A larger diameter allows for greater fluid flow, which is essential for high-volume applications. However, an excessively large diameter can lead to inefficiencies and higher costs. Conversely, a smaller diameter may restrict flow and result in increased pressure loss, which can adversely affect system performance. It's important to consider the specific requirements of your project and balance the diameter with the expected flow rates.

Wall thickness is equally important as it directly affects the pipe's strength and durability. Thicker walls can withstand higher pressures and are generally more resistant to corrosion, making them suitable for more demanding applications. However, while thicker pipes provide added strength, they also add to the weight and cost. In situations where weight is a limiting factor, or lower pressures are expected, opting for a thinner-walled pipe may suffice.

**Tips:** When selecting your pipe, assess the environmental factors, such as temperature and potential exposure to corrosive substances, which can influence the required wall thickness. Additionally, you may want to consult engineering standards and guidelines specific to your industry to ensure compliance and optimal performance.

When selecting the right stainless steel pipe for your project needs, assessing cost, availability, and supplier reliability is crucial for ensuring a successful outcome. First, consider the cost implications of the pipe materials. While stainless steel is generally more expensive than other materials, evaluating the long-term benefits, such as corrosion resistance and durability, is essential. An initial higher investment can lead to significant savings over time, particularly in demanding environments. It is also advisable to compare prices across multiple suppliers to ensure you are getting a competitive rate without compromising on quality.

Availability is another key factor that can significantly impact project timelines. Confirming that the desired pipe sizes and grades are in stock and ready for immediate delivery can prevent costly delays. It’s also wise to check suppliers' lead times for special orders, as some specific grades may require longer manufacturing processes. Additionally, researching supplier reliability is vital; this includes examining their track record of on-time delivery, customer reviews, and warranties or return policies. A reliable supplier not only helps in meeting deadlines but also provides peace of mind in the quality and performance of the materials provided.

| Pipe Diameter (inches) | Material Grade | Cost per Foot (USD) | Availability (Days) | Supplier Reliability (Rating out of 5) |

|---|---|---|---|---|

| 1 | 304 | $5.00 | 15 | 4.5 |

| 2 | 316 | $7.00 | 20 | 4.7 |

| 3 | Duplex | $8.50 | 25 | 4.2 |

| 4 | 430 | $4.00 | 10 | 4.0 |