Choosing the right round pipe for your project can be challenging. It's essential to understand the various options available. Industry expert John Smith once stated, “Selecting the proper round pipe is crucial for the success of your project.” This highlights the importance of making informed decisions.

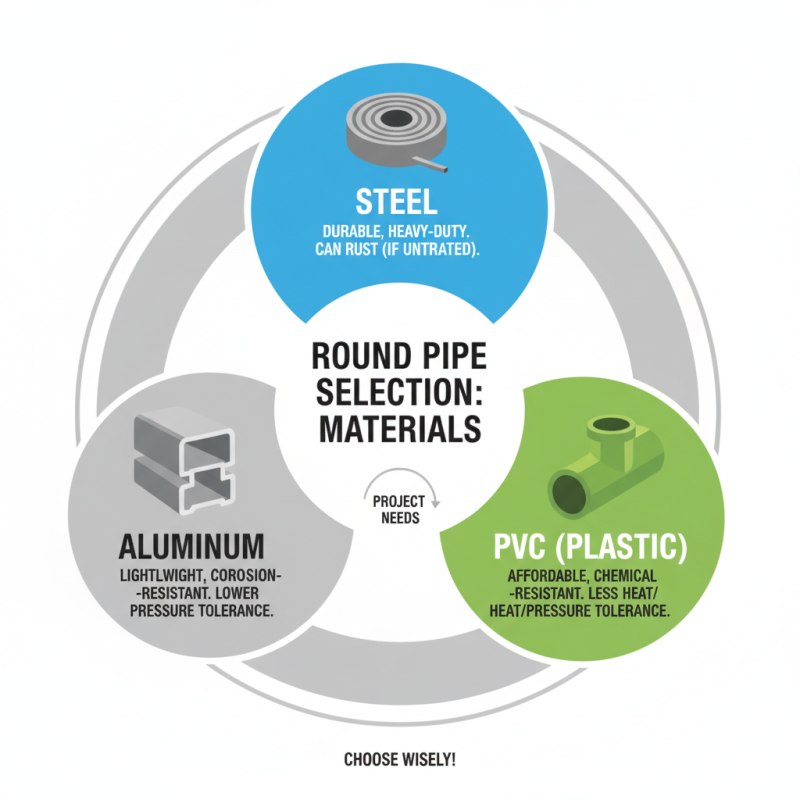

When considering round pipes, factors such as material, size, and application come into play. Steel, PVC, and aluminum are common materials. Each has its unique advantages and disadvantages. For instance, steel offers durability, while PVC is lightweight. It’s worth noting that not all pipes will suit every project.

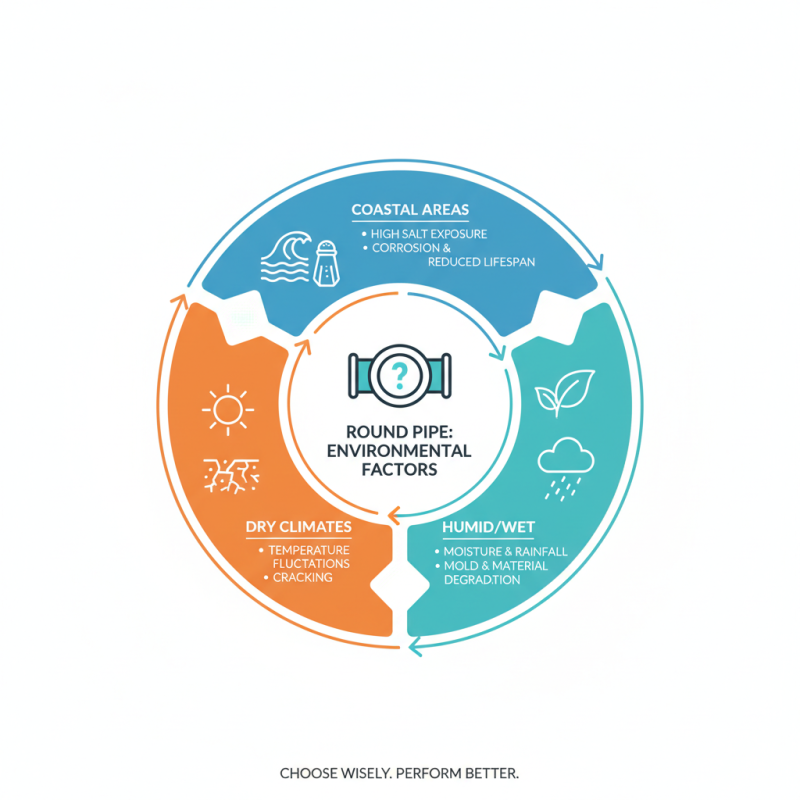

Often, engineers overlook the specific needs of their projects. This oversight can lead to costly mistakes and delays. Understanding the environment where the round pipe will be used is vital. Will it face high pressure or corrosion? These questions matter significantly in your choice. Reflecting on these details can improve your project's outcome.

Identifying project requirements is crucial when selecting round pipes. Start by considering the pipe's intended function. For structural applications, strength and durability are essential. According to industry reports, 70% of failures in piping systems stem from inadequate specifications. Misjudging material properties can spiral into costly repairs.

Next, think about the environment where the pipe will be used. Factors like temperature and exposure to chemicals can impact performance. For example, high humidity can lead to corrosion in certain materials. Reports indicate that corrosion costs the U.S. economy over $30 billion annually. It's vital to avoid overlooking these specifics, as they can drastically affect longevity and safety.

Lastly, dimensions play a significant role. Diameter and wall thickness must align with project needs. Interesting enough, industry guidelines highlight that over 40% of projects experience delays due to improper sizing. Engineers often underestimate the importance of accurate measurements. Taking the time to evaluate these factors can help prevent future setbacks.

| Project Type | Diameter (inches) | Material | Pressure Rating (psi) | Application |

|---|---|---|---|---|

| Plumbing | 1.5 | PVC | 150 | Water Supply |

| Drainage | 4 | HDPE | 0 | Stormwater Management |

| Gas Supply | 2 | Steel | 300 | Natural Gas Transport |

| HVAC | 6 | Aluminum | 200 | Air Circulation |

| Structural | 10 | Carbon Steel | 500 | Support Framework |

When selecting a round pipe, the material plays a crucial role. Different materials present unique advantages and drawbacks. For instance, steel pipes are durable and great for heavy-duty projects. However, they can rust if not treated. Aluminum pipes are lightweight and resist corrosion, yet they might not handle extreme pressure. Consider the specific needs of your project carefully.

Tips: Think about the environment where the pipe will be used. Will it be exposed to moisture? Rust could become a big problem. Look for protective coatings if you choose steel.

Another option is PVC. It’s affordable and easy to install. Still, PVC is not suitable for high-temperature applications. If your project involves hot liquids, this may not be the right choice. Pay attention to compatibility with other materials too.

Tips: Measure twice, cut once. Ensure accurate dimensions when purchasing. A small mistake can lead to larger issues down the line. Always double-check the specifications before making a decision.

Choosing the right round pipe starts with understanding sizes and dimensions. When assessing pipe options, you should consider the pipe's diameter and wall thickness. These factors directly influence flow capacity and structural integrity. For instance, a larger diameter allows for greater fluid movement but may require more space for installation.

It's essential to measure your project space accurately. Many times, users underestimate dimensions, leading to fitting issues. The wrong size can result in leaks or inadequate support. Placement can also affect your choice. Pipes located in tight areas might necessitate thinner walls for easier installation.

Different projects may require varying factors for optimal fit. Reflect on your specific needs, such as flow rates or material properties. Adjustments may be necessary based on the environment. Be prepared for challenges when finalizing dimensions. This thoughtful approach often separates successful projects from the less effective ones.

When choosing a round pipe, environmental factors play a crucial role. Different environments can dramatically affect the performance of pipes. For instance, pipes used in coastal areas face high salt exposure. This can lead to corrosion and reduced lifespan. In contrast, pipes in dry climates may experience less wear but could be prone to cracking due to temperature fluctuations.

The material of the pipe is essential to consider. Some materials react poorly to UV light, while others may degrade in extreme temperatures. Analyze the specific conditions of your project site. Rain, heat, or even industrial pollution can impact pipe functionality. Mistakes in material selection can lead to project delays and increased costs.

Experts recommend long-term testing for performance in varied conditions. Field measurements are often more revealing than theoretical data. However, many overlook this. They rely solely on manufacturer specifications or past experiences. Real-life conditions often differ from expected outcomes. Understanding your environment will guide you in choosing a pipe that meets your needs effectively.

Choosing the right round pipe for your project involves careful analysis of cost and availability. Begin by estimating your budget. Round pipes come in various materials, each with different price points. Steel and PVC may be cheaper than copper, but they serve different purposes. Consider the long-term costs, not just the initial purchase.

Availability is another critical factor. Some materials may be scarce in your area. Check local suppliers and online platforms. Ensure they stock the pipe sizes and materials you need. There may be delays, especially for specialized pipes. Be prepared for potential challenges.

Sometimes, you may face unexpected hurdles. A pipe you believed was readily available could be on backorder. If that happens, reassess your options. Look for alternatives or adjust your project timeline. Being flexible can save you time and costs. Take the time to evaluate every detail before committing to a specific round pipe.

This chart illustrates the cost per meter of various types of round pipes commonly used in construction and plumbing projects. PVC is the most economical option while copper is the most expensive.