Choosing the right metal coils for your project can be challenging. Metal coils come in various materials, sizes, and finishes. Understanding the specific needs of your project is crucial. Consider the application where these coils will be used. Will they be exposed to moisture, heat, or other elements? These factors influence the choice of metal.

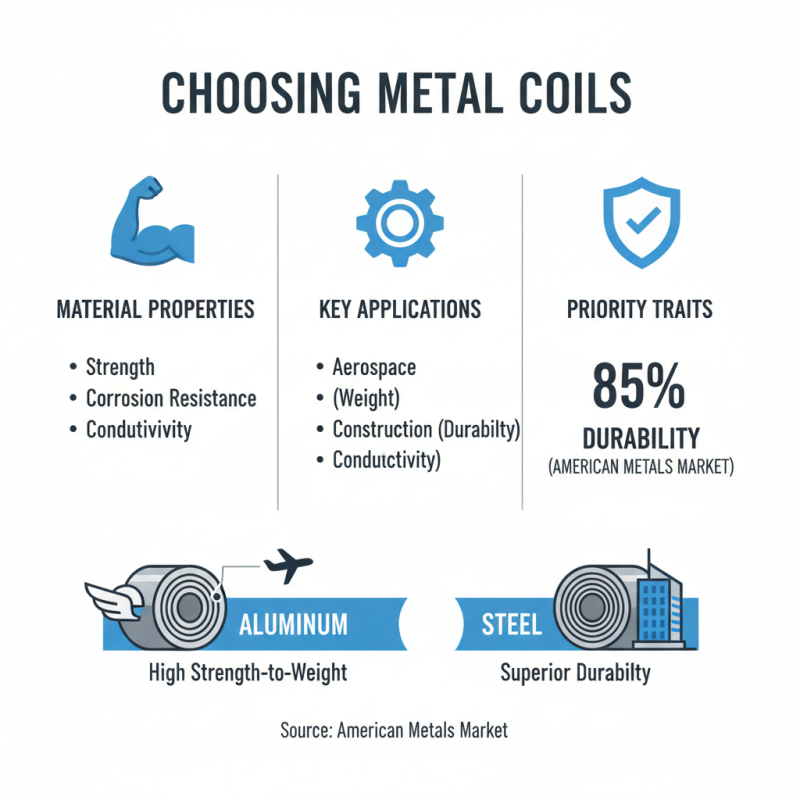

Different types of metal coils serve unique purposes. For example, aluminum coils are lightweight and resistant to corrosion. Steel coils offer strength and durability. Copper coils are excellent for electrical applications. Each has its advantages and limitations. This complexity can be overwhelming, forcing one to reflect on what truly matters for their project.

Think about the cost, as well. High-quality metal coils may be more expensive but can save money in the long run. Sometimes, cutting corners by choosing cheaper options could backfire. Ensure you weigh all these considerations carefully. The right choice makes a significant impact on overall project success.

Choosing the right metal coil for your project involves understanding various types available in the market. Steel coils are common and widely used. They provide strength and durability for construction. Aluminum coils are lightweight and resistant to corrosion. This makes them ideal for outdoor applications. Copper coils offer excellent conductivity. They are often used in electrical applications.

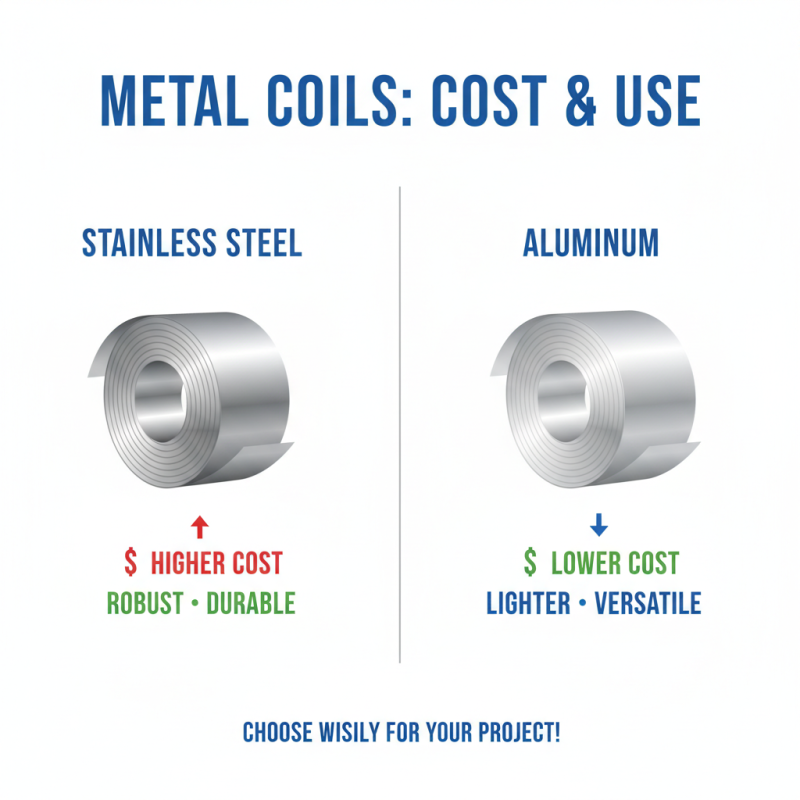

Each type of metal coil has its own unique characteristics. Stainless steel coils resist rust and stains. However, they tend to be more expensive. Galvanized coils, coated with zinc, offer additional protection. They are often used in roofing and siding projects. Choosing the right coil depends on the specific needs of your project.

Some projects require heavy-duty materials. Others need flexible, lightweight options. It may be tempting to go with the cheapest option. But, that can lead to unexpected problems later. Take the time to weigh each type against project requirements. Each decision can impact both cost and performance.

| Type of Metal Coil | Material Composition | Thickness (mm) | Applications | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum Coil | Aluminum 1100 | 0.5 - 10 | Construction, Aerospace | Good |

| Copper Coil | Copper C11000 | 0.3 - 8 | Electrical, Plumbing | Excellent |

| Stainless Steel Coil | Stainless Steel 304 | 0.5 - 12 | Food Processing, Chemical | Very Good |

| Galvanized Steel Coil | Low Carbon Steel | 0.4 - 6 | Roofing, Fencing | Good |

| Carbon Steel Coil | Carbon Steel S235 | 1.0 - 15 | Manufacturing, Construction | Fair |

Choosing the right metal coils hinges on understanding their material properties. Different applications require specific traits. For example, strength, corrosion resistance, and conductivity are vital. The American Metals Market states that 85% of metal coil uses prioritize durability. Aluminum coils often have a better strength-to-weight ratio compared to steel. This is crucial for aerospace applications, where every gram matters.

Thickness and gauge also impact performance. A report by metal production experts notes that a 0.25 mm aluminum coil can handle much stress yet remains lightweight. If your application demands precise tolerances, consider this carefully. Steel, on the other hand, excels in high-temperature environments. However, it may need additional coatings for increased rust resistance.

Don’t overlook the potential for errors in selecting metal properties. Relying solely on manufacturer specifications may lead to unsuitable material choices. Some users have faced failures due to misjudging thickness or mechanical properties. Reflecting on what you truly need versus what is readily available can save time and resources. Understanding the applications deeply can guide you toward the right choice.

When selecting metal coils for a project, thickness and gauge are crucial factors. Thickness refers to the actual physical measurement, while gauge is a standardized representation of thickness. It’s important to understand how these measurements affect the material’s durability and functionality. A thicker coil generally provides greater strength. However, it may be more challenging to work with. Balancing strength and flexibility is essential.

Different applications may require varied gauges. A thinner gauge may be suitable for lightweight structures, while heavy machinery may demand thicker options. It's necessary to think about the end use. If unsure, consulting with experts can help. Often, people overlook this aspect and face challenges later on.

Measuring thickness accurately can be tricky. Sometimes, gauges are not straightforward. Variations between standards can lead to confusion. It’s essential to double-check measurements and specifications. Even minor errors can cause significant issues in a project. Taking time to assess these requirements will save time and resources in the long run.

When considering metal coils for a project, cost-effectiveness is key. Different materials come at varying prices. Stainless steel is robust but often higher-priced. Aluminum offers a lighter option, usually at a lower cost. Both have their uses.

Tips: Always calculate your budget first. It helps focus your choices. Look beyond the upfront costs. Think about longevity and maintenance too. The cheapest option may not save you money in the long run.

Evaluate your specific needs. Consider the coil thickness and finish. Thicker coils often cost more but provide durability. Finish affects appearance and functionality. Remember, what looks good may be pricier. Sometimes, a less shiny option could fit your project better while saving cash.

Research local suppliers for better deals. They may offer discounts or bulk pricing. Keep in mind that transporting heavy coils can add hidden costs. Plan accordingly to avoid surprises later.

When selecting metal coils for your project, evaluating supplier reliability is crucial. A trustworthy supplier ensures that you receive high-quality materials. Begin by checking reviews or testimonials from previous clients. This can reveal the supplier's strengths and weaknesses. Look for patterns in feedback; frequent complaints may indicate issues.

Delivery considerations are equally important. Delays can disrupt your project timeline. Verify the supplier's shipping options and timelines. Some suppliers may promise quick delivery but fail to meet deadlines. It's wise to ask for a detailed shipping schedule. Making sure your supplier can accommodate your needs is essential.

Tips: Always communicate your requirements clearly. This step prevents misunderstandings. Establishing a good relationship with the supplier can lead to better service. Don't hesitate to ask questions about their production capabilities. Assessing their response time can indicate their level of professionalism. Overall, these factors together help ensure a smooth project experience.