Choosing the right cold rolled sheet for your project needs is crucial in ensuring optimal performance and results. Cold rolled sheets are known for their smooth surface finish, enhanced dimensional accuracy, and increased strength compared to hot rolled sheets. These characteristics make cold rolled sheets a preferred choice in a variety of applications, from construction and automotive manufacturing to appliances and furniture. However, with the wide selection of cold rolled sheets available in the market, it can be challenging to identify the specific type that best aligns with your project requirements.

In this guide, we will explore several key factors to consider when selecting cold rolled sheets. Understanding the properties, such as thickness, width, and yield strength, is essential, as these attributes significantly influence the material's suitability for the intended application. Additionally, we will discuss how processing methods and surface treatments impact the performance and appearance of cold rolled sheets. Armed with this knowledge, you will be better equipped to make informed decisions that enhance the quality and longevity of your project.

When selecting cold rolled sheets for engineering projects, several critical factors come into play. First and foremost, the thickness of the sheet should align with the specific requirements of your project. Thicker sheets offer enhanced strength and durability, making them ideal for heavy-duty applications, while thinner sheets provide improved formability and are suitable for lighter structural needs. Additionally, the gauge of the sheet can impact the material's weight, cost, and ease of handling, so it's important to evaluate these aspects in the context of your project specifications.

Another important consideration is the surface finish of the cold rolled sheets, which can affect both aesthetic quality and functionality. A smooth surface finish is often required for applications that demand high precision, as it prevents defects during further processing like painting or machining. In contrast, a rougher finish might be acceptable for applications where appearance is less critical. Furthermore, the type of steel used, whether it be low carbon, high carbon, or a stainless variant, will determine the sheet's properties, including corrosion resistance and mechanical strength, influencing its suitability for different environments and applications. Always ensure that the selected sheet meets industry standards to guarantee performance and reliability in your engineering project.

When selecting a cold rolled sheet for your project, understanding the mechanical properties of the material is essential. Cold rolled steel sheets are known for their excellent tensile strength, which makes them ideal for applications requiring durability and resistance to deformation. Their yield strength is also higher than that of hot rolled sheets, providing enhanced performance in structural applications. The precise machining capabilities of cold rolled steel allow for tighter tolerances and a smoother finish, making it a preferred choice in manufacturing processes where accuracy is critical.

Tips: When assessing the mechanical properties, consider the specific demands of your project. For example, if your application involves bending or forming, pay attention to the elongation percentage, as it indicates how much the material can stretch before breaking. Additionally, a higher hardness value may be desirable for wear resistance but can also make the material more challenging to work with, so balance is key.

Another critical aspect of cold rolled sheets is their corrosion resistance. Although they are typically coated or galvanized for added protection, the inherent properties of cold-rolled steel can influence its performance in various environments. Thus, analyzing the expected exposure conditions and the material’s treatment options can help ensure longevity and reliability in your project. When selecting the thickness or gauge, remember that thinner sheets increase flexibility, while thicker sheets provide improved strength and stiffness, so choose based on your specific mechanical requirements.

| Property | Value | Unit | Importance for Projects |

|---|---|---|---|

| Yield Strength | 250 | MPa | Critical for load-bearing applications |

| Tensile Strength | 400 | MPa | Indicates maximum load before failure |

| Elongation | 15 | % | Measures ductility for forming processes |

| Hardness | 80 | HRB | Important for wear resistance |

| Thickness | 1.5 | mm | Determines strength and application suitability |

| Width | 1000 | mm | Essential for fitting in designated spaces |

| Coating | Zinc Coated | - | Enhances corrosion resistance |

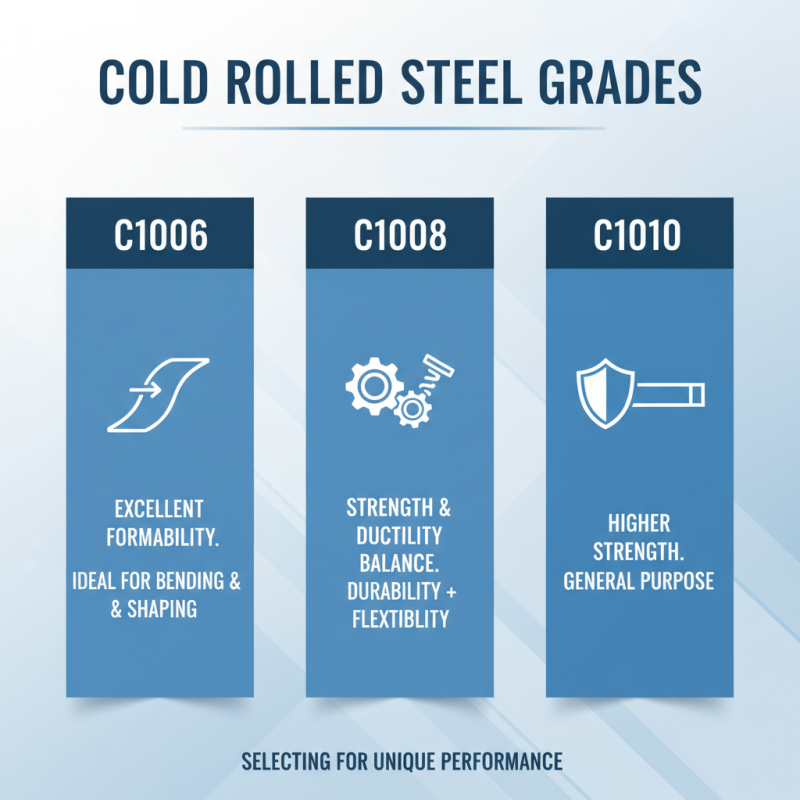

When selecting cold rolled steel for specific applications, it is essential to understand the different grades available, each tailored for unique performance requirements. Common grades of cold rolled steel include C1006, C1008, and C1010, among others. C1006, for example, is known for its excellent formability and is often used in applications that require bending and shaping. In contrast, C1008 provides a balance of strength and ductility, making it suitable for parts that demand both durability and flexibility.

Another grade, C1010, offers higher tensile strength and is ideal for applications that undergo significant stress. This grade is often chosen for automotive and structural components where reliability is critical. By examining the specific mechanical properties such as yield strength, tensile strength, and elongation, you can better match the right cold rolled sheet to your project's demands. Understanding these distinctions not only enables more efficient production but also ensures that the final product meets functional and safety standards.

When manufacturing products that require cold rolled sheets, it’s essential to conduct a thorough cost analysis to ensure the chosen materials align with your budget constraints. Cold rolled sheets offer a range of benefits, such as enhanced surface finish and tighter tolerances, which can make them more expensive than their hot rolled counterparts. To effectively budget for these materials, you should consider factors such as the sheet thickness, dimensions, and the overall volume needed for your project. Higher demand for specific grades or finishes can lead to fluctuations in pricing, so it's wise to monitor market trends and supplier pricing closely.

Additionally, incorporating a comprehensive cost analysis involves assessing not only the price of the sheets themselves but also the associated fabrication costs. Expenses related to cutting, welding, and surface treatment should be factored into your overall budget. Moreover, considering the total lifecycle cost of using cold rolled sheets is crucial. They may have a higher upfront cost, but their durability and resistance to wear could result in lower maintenance and replacement expenses over time. By evaluating all of these aspects, you can make a well-informed decision that meets both your quality requirements and budgetary limits.

When selecting cold rolled steel sheets for your project, evaluating the surface finish options is crucial to ensuring the material meets your aesthetic and functional requirements. Cold rolled sheets typically feature various surface finishes, such as bright, matte, or textured, each contributing differently to the overall appearance and performance of the steel. A bright finish, for instance, can enhance the reflective qualities of the steel, making it suitable for applications where visual appeal is important, such as in design elements or fixtures.

Another consideration is the matte finish, which can provide a subtle, understated look while also offering better resistance to fingerprints and smudges. This option is particularly useful in environments where cleanliness is a priority, such as in food processing or clean room applications. Textured finishes add another layer of functionality, often improving grip and reducing the likelihood of scratching. Therefore, understanding these surface finish options and their implications will guide you toward making an informed choice that aligns with your specific project needs.