When selecting materials for construction and manufacturing, many industries prioritize durability and quality. Stainless Steel Plate stands out among options due to its numerous advantages. Reports indicate that the global stainless steel market is projected to grow by 5.5% annually through 2025. This growth reflects the rising demand for materials that can withstand corrosion and extreme conditions.

Stainless Steel Plate offers excellent resistance to rust and staining. It is particularly vital in sectors like food processing and pharmaceuticals. A recent study noted that over 70% of manufacturers favor stainless steel for its hygiene properties. However, there are challenges to consider. The initial cost can be higher compared to alternatives, leading some to hesitate. Yet, the long-term savings in maintenance often justify the investment.

In conclusion, Stainless Steel Plate remains a critical choice for many industries. Its strength, longevity, and resistance to harsh environments make it indispensable. With the right approach, businesses can harness its benefits effectively. Reflecting on material choices is essential for ensuring project success.

When considering materials for construction, stainless steel plates stand out. Their corrosion resistance is one of the main advantages. Builders face challenging environments. Substances like saltwater and humidity can cause damage. Stainless steel plates withstand these conditions well. They maintain structural integrity over time. This is crucial for long-term projects.

Another key benefit is their strength-to-weight ratio. Stainless steel plates provide durability without being overly heavy. This makes them easy to transport and install. However, handling them requires care. Improper lifting can lead to accidents, so safety protocols are essential. Training for workers is often overlooked but vital.

Aesthetic appeal also plays a role. Stainless steel plates offer a modern look. They can enhance the visual aspect of buildings. However, fingerprints and smudges can be an issue. Regular cleaning is necessary to maintain their shine. Despite these challenges, the advantages often outweigh the drawbacks.

When selecting materials for projects, durability is crucial. Stainless steel plates offer exceptional longevity compared to alternatives like aluminum or plastic. These plates resist rust, corrosion, and wear, making them ideal for harsh environments. Unlike other materials, stainless steel withstands high temperatures and maintains structural integrity over time.

Tips: Consider the environment. If exposure to moisture is a concern, stainless steel excels in preventing damage. Evaluate your project's specific needs. Stainless steel can handle heavy loads, making it suitable for construction or fabrication.

While stainless steel plates are durable, they are not entirely impervious. Scratches and dents can occur, especially if mishandled. Regular maintenance can mitigate potential weaknesses. Periodically checking for surface flaws is wise to ensure continued strength. Remember, no material is perfect, and adaptability is key.

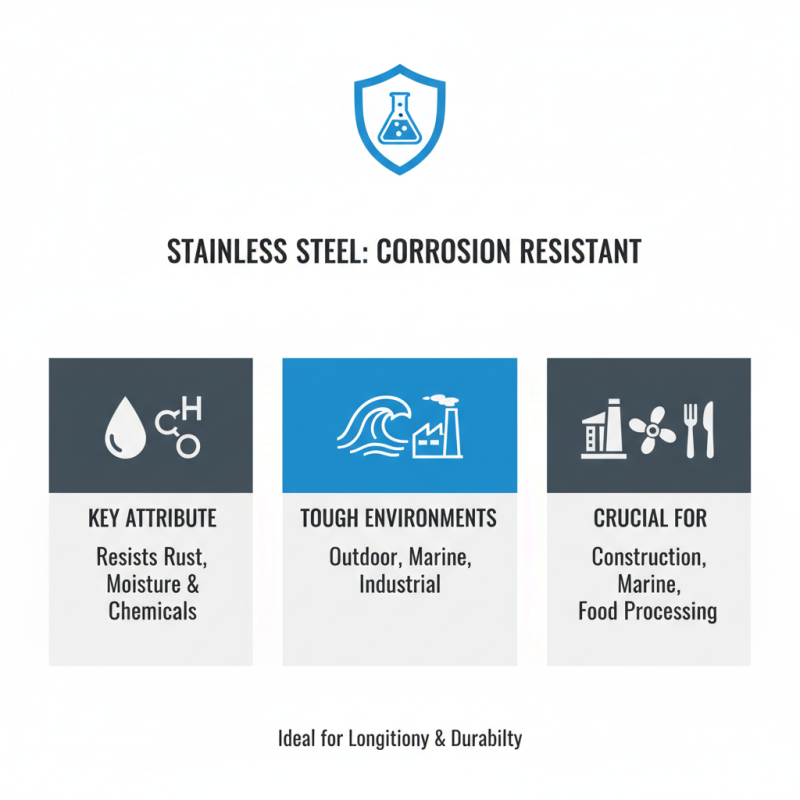

Corrosion resistance is a vital attribute of stainless steel plates. When selecting materials for projects, this quality often stands out. Stainless steel can withstand harsh environments, including moisture and chemicals. It doesn’t rust easily, which makes it suitable for outdoor applications. This feature is crucial in industries like construction, marine, and food processing.

However, not all stainless steel varieties offer the same level of corrosion resistance. Factors such as grade and alloy composition come into play. Some plates perform better than others against specific corrosive elements. This inconsistency can lead to unexpected failures in projects. Choosing the right stainless steel requires careful consideration and understanding of your project's unique demands.

It's also important to remember that corrosion resistance doesn't mean complete immunity. Stainless steel can still suffer from pitting and crevice corrosion under certain conditions. Regular maintenance and monitoring are necessary to ensure optimal performance. Attention to these details can make a significant difference in the longevity of your projects.

When considering materials for a project, stainless steel plates emerge as a compelling choice. Their durability is a key aspect. Unlike other metals, they resist corrosion and wear over time. This means fewer replacements are needed. In the long run, this significantly reduces costs.

The initial investment in stainless steel plates might seem high. However, longevity compensates for this initial expense. These plates endure harsh conditions, minimizing maintenance costs. Companies can save on labor and downtime, which adds to financial benefits. A project may face setbacks due to rust or damage with cheaper alternatives. In contrast, stainless steel plates maintain performance.

One should reflect on potential mistakes. Choosing the cheaper option may seem wise initially. However, hidden costs can mount. Over time, repeated repairs can exceed the initial savings. Balancing short-term savings with long-term value leads to wiser decisions. Projects deserve reliable materials that stand the test of time. Stainless steel promises this, making it a worthy consideration.

| Project Type | Stainless Steel Plate Cost ($/sq ft) | Alternative Material Cost ($/sq ft) | Lifespan (Years) | Maintenance Frequency (Times/Year) | Total Long-Term Cost ($) |

|---|---|---|---|---|---|

| Residential Kitchen | 5.50 | 4.00 | 15 | 1 | 145.00 |

| Commercial Kitchen | 6.00 | 4.50 | 20 | 2 | 140.00 |

| Industrial Applications | 7.50 | 5.50 | 25 | 1 | 160.00 |

| Architectural Design | 8.00 | 6.00 | 30 | 1 | 240.00 |

Stainless steel is a popular choice in construction due to its durability and sleek appearance. Yet, its environmental impact deserves attention. This material is 100% recyclable, which greatly reduces waste. When projects end, stainless steel can be repurposed without losing quality. This characteristic cuts down on the energy needed for new materials.

However, the production of stainless steel comes with its challenges. The process requires significant energy and can generate greenhouse gases. It's essential to reflect on these aspects. Efforts are being made to improve the efficiency of production methods. Sustainable practices are becoming more common, but there's a long way to go.

Incorporating stainless steel can support sustainability, but awareness of the entire lifecycle is crucial. Choosing this material is a step towards reducing environmental impact. Yet, each project must analyze how it contributes to a sustainable future. Ultimately, the focus should remain on continuous improvement in our choices.