Choosing the right Carbon Steel Plate for your project is crucial for achieving optimal performance and durability in various applications. According to the World Steel Association, carbon steel constitutes about 90% of the world's steel production, highlighting its significance in construction, automotive, and manufacturing industries. Furthermore, a report by Technavio projects that the global carbon steel plate market will grow at a CAGR of over 4% from 2021 to 2025, driven by rising demand for infrastructure development and industrialization. Understanding the specific requirements of your project, including factors such as thickness, grade, and processing methods, can significantly impact the quality and efficiency of your construction outcomes. Therefore, making an informed decision about selecting the right Carbon Steel Plate is not only essential for adhering to industry standards but also for maximizing the longevity and cost-effectiveness of your project.

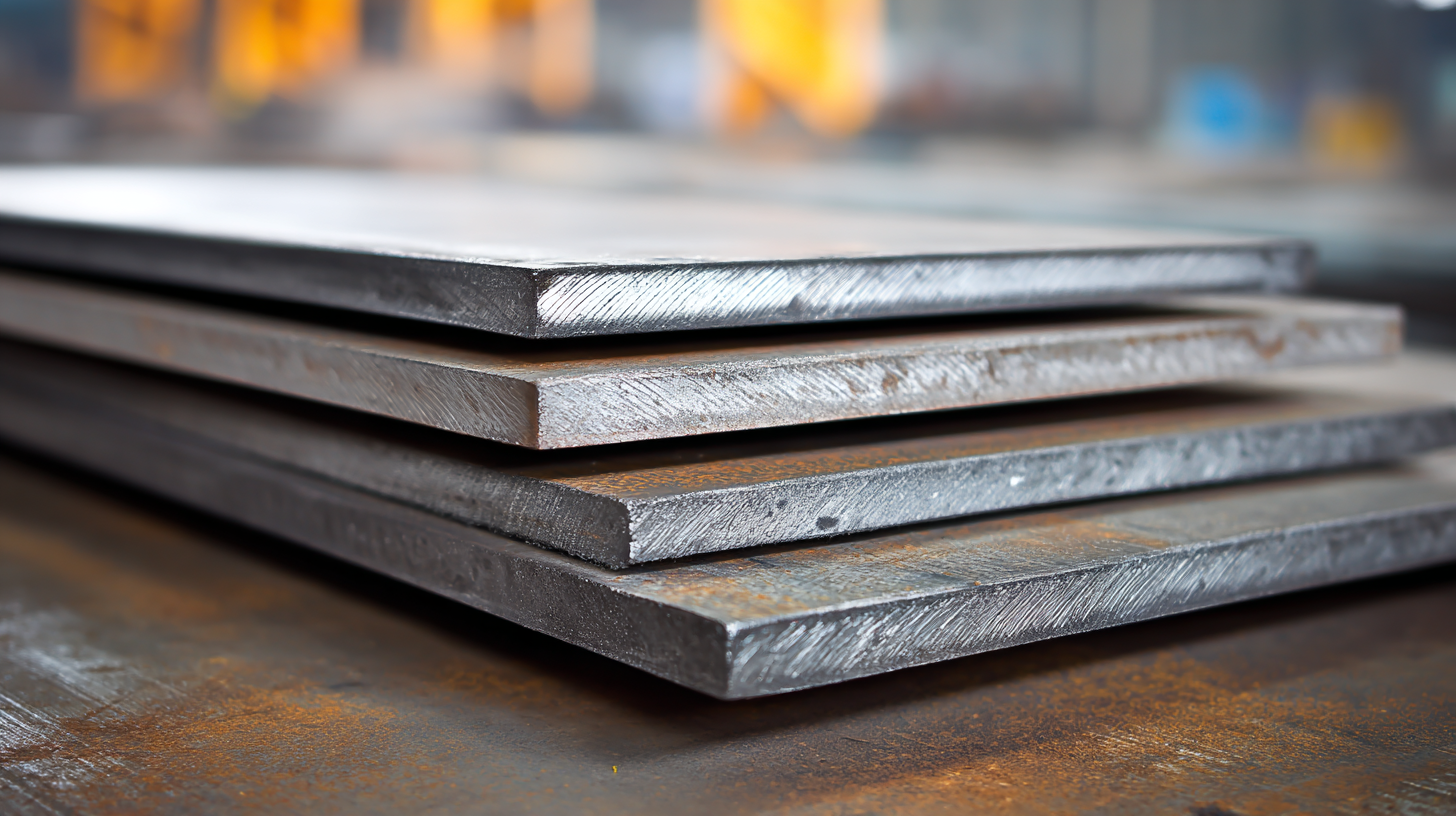

When selecting a carbon steel plate for your project, understanding the different grades is crucial for ensuring suitability and performance. Carbon steel plates are generally categorized into low, medium, and high carbon grades, each offering distinct mechanical properties and applications. According to the American Society for Testing and Materials (ASTM), low carbon steel (Grade A36) is commonly used for structural applications due to its excellent weldability and cost-effectiveness. It typically contains 0.26% to 0.29% carbon, making it ductile and easy to shape.

Medium carbon steels, such as A572, range from 0.30% to 0.60% carbon content and provide a higher strength than low carbon alternatives. This grade is ideal for applications requiring good wear resistance. Furthermore, high carbon steels, which exceed 0.60% carbon content, are utilized in manufacturing tools and heavy-duty components due to their exceptional hardness and strength. Industry reports indicate that selecting the appropriate grade can enhance the performance and longevity of your project, ultimately impacting operational efficiency and costs. Understanding these grades allows project managers to optimize material selection based on project requirements and expected loads.

When selecting the appropriate carbon steel plate for a project, understanding mechanical properties and chemical composition is crucial. Mechanical properties, such as tensile strength, yield strength, and hardness, dictate how the steel will perform under various loads and environmental conditions. For instance, higher carbon content typically increases hardness and strength but may reduce ductility. Therefore, it is essential to align these properties with the specific demands of the application, whether it’s construction, manufacturing, or any specialized engineering task.

In addition to mechanical attributes, the chemical composition of carbon steel plays a vital role in determining its suitability for a project. Elements like manganese, silicon, and phosphorus influence not only strength and hardness but also how the steel reacts to heat treatment and welding processes. For example, certain alloys might be better suited for high-temperature applications due to their ability to maintain structural integrity. By thoroughly evaluating both the mechanical properties and the chemical makeup, engineers and project managers can make informed decisions, ensuring the selected carbon steel plate meets performance criteria and extends the lifespan of the finished product.

When selecting carbon steel plates for your project, it is crucial to assess the thickness and size requirements based on industry standards. According to the American Society for Testing and Materials (ASTM), various grades of carbon steel are categorized by their thicknesses, which typically range from 0.049 inches to over 0.5 inches for structural applications. This range is significant because the thickness directly influences the plate's strength and its suitability for high-stress environments.

In addition, the standard sizes of carbon steel plates also play a critical role in project success. Industry standards, such as those set forth by the standardization organizations like the American National Standards Institute (ANSI), typically specify dimensions like 48”x96” or 60”x120”. These sizes ensure compatibility with common fabrication techniques and machinery, thereby reducing waste and improving efficiency. By adhering to these established dimensions and thickness guidelines, engineers can optimize their designs to meet safety standards while simultaneously accommodating specific project needs.

When selecting a carbon steel plate for your project, understanding the impact of carbon content is essential, particularly regarding hardness and weldability. Carbon content in steel typically ranges from 0.05% to over 2.0%, with higher levels leading to increased hardness. For instance, steels with carbon content around 0.3% to 0.7% strike a balance between hardness and ductility, making them suitable for applications like structural components and tools. This hardness arises from the formation of harder microstructures like martensite when subjected to heat treatment.

However, increased carbon content can adversely affect weldability. Higher carbon steels tend to be more brittle and prone to cracking during welding processes. Therefore, appropriate measures, such as preheating the material and selecting suitable welding techniques, are critical when working with high carbon content plates. For projects requiring strong, durable seams, using a moderate carbon content steel can facilitate better weld penetration and overall integrity. Understanding these nuances ensures that you select the right carbon steel plate tailored to your project's needs.

| Carbon Content (%) | Hardness (Brinell HB) | Weldability Rating | Common Applications |

|---|---|---|---|

| 0.05 | 145 | Excellent | General fabrication |

| 0.15 | 150 | Good | Structural components |

| 0.30 | 180 | Fair | Manufacturing tools |

| 0.50 | 210 | Poor | Cutting tools, dies |

| 0.80 | 250 | Very Poor | High-strength wires |

When procuring carbon steel plates, it is essential to strike a balance between quality and budget. High-quality carbon steel often comes with a premium price tag, but investing in better materials can lead to improved durability and performance in your project. Understanding the specific requirements of your application, such as tensile strength, corrosion resistance, and weldability, will help you determine the necessary quality level. In many cases, opting for slightly higher quality steel can save costs in the long run by reducing maintenance and replacement needs.

Cost considerations also involve analyzing the supplier's offerings. Different manufacturers may provide varying levels of quality and pricing. It is crucial to research and compare not only the prices but also the reputation of suppliers, their production processes, and customer reviews. Additionally, bulk purchasing or negotiating contracts can lead to better pricing, making it more feasible to adhere to your budget without compromising on quality. Ultimately, a thoughtful approach to balancing these factors will ensure that your project meets both performance expectations and financial constraints.