When it comes to construction, choosing the right materials is crucial. Steel plates are essential for many structural applications. Renowned steel plate expert, Dr. Emily Hayes, once stated, "Selecting the right steel plate can make or break a project." This highlights the importance of understanding different types of steel plates available.

Different projects require different steel plate types based on strength, thickness, and durability. For example, structural steel plates are often used in building frameworks, while specialized steel is needed for heavy machinery. Each type has unique properties that impact the overall performance of a construction project.

However, despite the advantages, some challenges come with selecting steel plates. Poor quality choices can lead to costly failures. It’s vital to conduct proper research. Builders and engineers should weigh their options carefully. Each project is unique, making it essential to find the right match.

When it comes to construction projects, choosing the right steel plate is essential. Various types of steel plates serve different purposes. For example, structural steel plates are robust and can support heavy loads. They are often used in girders or beams. These plates come in various thicknesses and sizes, making them versatile for numerous applications.

Another common type is the carbon steel plate. It's cost-effective and easy to weld. This makes it a popular choice for many construction tasks. However, its susceptibility to rust is a consideration. Proper coating or treatment can help with corrosion resistance, but it requires careful planning.

Then there's the stainless steel plate. While more expensive, it resists corrosion better. This is crucial in environments exposed to harsh weather.

Every type of steel plate has its advantages and drawbacks. Selecting the right one is about understanding project requirements. Failures can arise from overlooking important details. For example, using the wrong plate thickness can lead to structural weaknesses. Thus, careful thought and consideration are needed to ensure a successful construction outcome.

When selecting steel plates for construction, understanding their key properties is crucial. Steel plates are vital for structural integrity and durability. They provide essential support in various applications, from buildings to bridges. The strength of steel is determined by its composition and processing. According to a study by the American Institute of Steel Construction (AISC), stronger steel plates can withstand higher loads, leading to safer structures.

Ductility is another important property. It allows steel plates to deform without breaking. This is vital in seismic zones where structures face dynamic forces. Research indicates that ductile steel can absorb energy and prevent catastrophic failures. The Material Properties Handbook notes that materials with poor ductility are prone to sudden fractures, highlighting the need for careful selection.

Corrosion resistance is often overlooked. Steel plates exposed to the environment must resist rust and degradation. For example, a report from the International Corrosion Council recommends appropriate coatings to enhance longevity. Many builders fail to consider this aspect, risking structural performance. Choosing the right steel plate means balancing multiple factors: strength, ductility, and corrosion resistance are all essential for your project’s success.

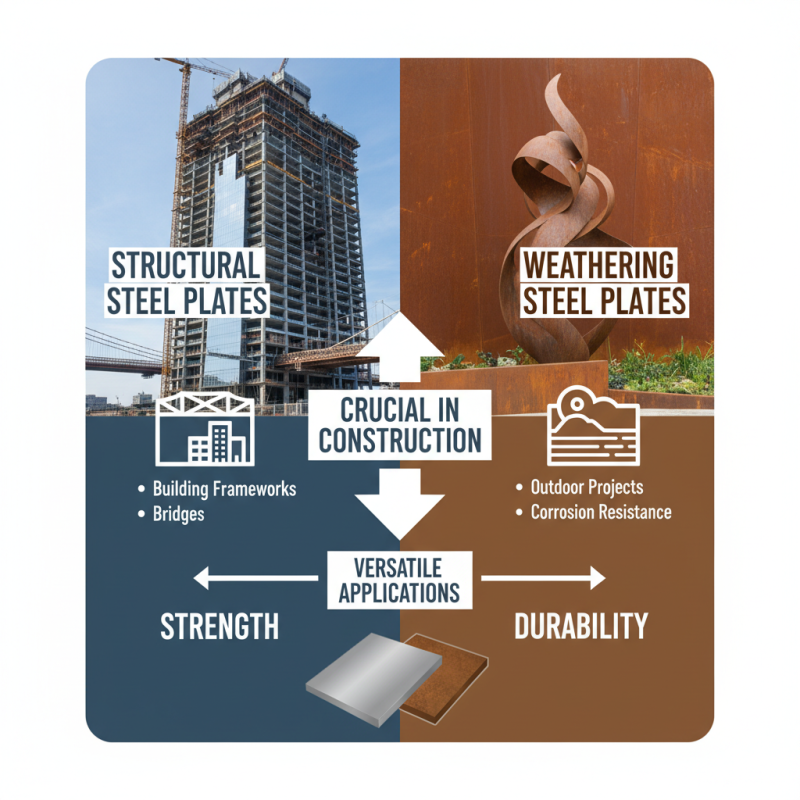

Steel plates are crucial in various construction sectors. Different types serve unique applications. For example, structural steel plates are vital for building frameworks and bridges. Their strength and durability allow them to support heavy loads. In contrast, weathering steel plates develop a rust-like appearance, providing protection against corrosion. This makes them ideal for outdoor projects.

Another type, shipbuilding steel plates, is essential in maritime construction. These plates withstand harsh marine environments. Their resistance to seawater corrosion is impressive. On the other hand, boiler and pressure vessel plates require precision in fabrication. They must handle extreme temperatures and pressures safely. Each type of steel plate plays a distinct role, yet some projects may misjudge their specific needs.

Despite advances, challenges remain. The selection of steel plates can be daunting. A wrong choice may lead to structural failures. Construction teams need to evaluate their options carefully. Misunderstanding the properties and applications of each plate type can be costly. Regular training and up-to-date knowledge are necessary in this evolving industry.

When selecting steel plates for construction, several factors must be considered. The grade of the steel is crucial. Different grades provide varying levels of strength and corrosion resistance. For example, mild steel offers flexibility while high-strength steel is ideal for heavy load-bearing structures. Choose based on your specific project needs.

Thickness is another important aspect. Thicker plates often provide better durability but can be heavier and more costly. If you're unsure, consult with a specialist. They can guide you on the right balance between cost and performance. Environmental exposure also plays a role in material choice. If a project is in a harsh environment, protective coatings might be necessary.

Don’t forget about weldability. Some steel types are easier to weld than others, impacting fabrication processes. Poor weldability can lead to project delays or structural issues. Always review your project scope and requirements. Keep in mind that every choice carries trade-offs. A thorough evaluation is necessary to meet both current and future needs.

When choosing steel plates for construction, costs and performance are essential considerations. Different types of steel plates come with varying properties and price points. For example, carbon steel plates are widely used due to their affordability and strength. However, they may lack corrosion resistance, which can lead to higher maintenance costs over time.

Stainless steel plates offer excellent durability and resistance to rust. While they are more expensive upfront, they often prove cost-effective in the long run. These plates are ideal for projects requiring longevity. On the other hand, alloy steel plates can provide a balance of strength and cost-effectiveness. Yet, their specific properties can vary significantly, making it crucial to evaluate each option carefully.

It's important to recognize that no single type of steel plate meets all needs perfectly. Depending on the project's requirements, trade-offs are often necessary. Weighing the initial costs against potential long-term expenses can be tricky. The choice should align with both immediate budget constraints and future performance expectations. Making informed decisions requires a thorough understanding of each steel plate type.