Galvanized pipes are widely used in construction and plumbing projects. Their coated surface prevents rust and extends their lifespan. According to the latest industry report by the American Galvanizers Association, the longevity of galvanized pipes can exceed 50 years under ideal conditions. This makes them a reliable choice for many applications.

Expert in the field, Dr. Samuel Reed, states, "Choosing the right galvanized pipe can significantly impact your project's durability." This highlights the importance of selecting the best product. Factors like thickness, coating quality, and manufacturer reputation affect the performance of galvanized pipes.

Despite their benefits, challenges exist in the galvanized pipe market. Some products may not meet quality standards. Additionally, corrosion can occur if not properly installed. These issues emphasize the need for careful consideration when selecting galvanized pipes for your next project.

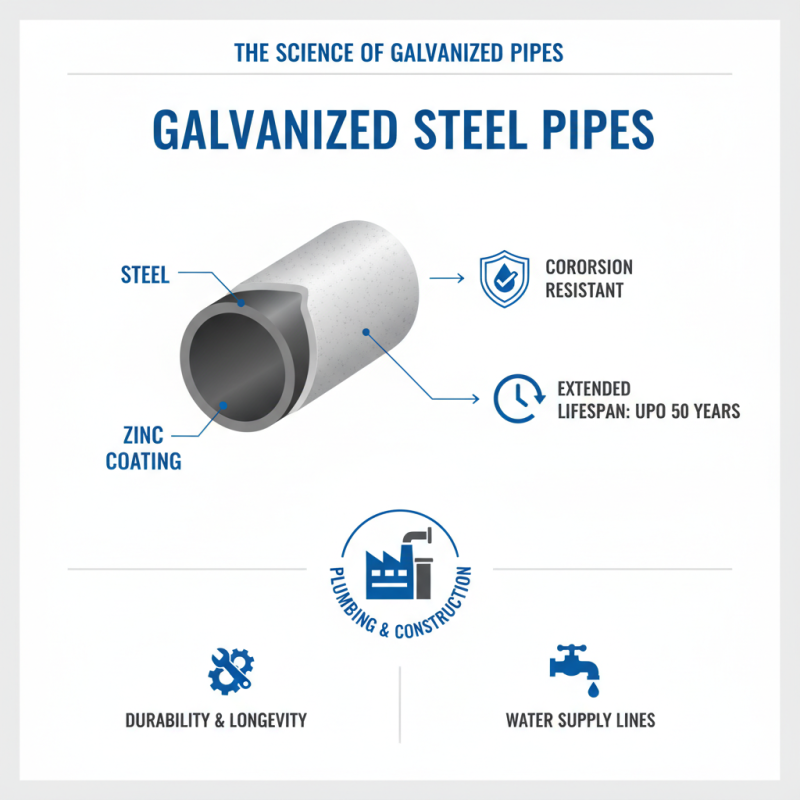

Galvanized pipes are steel pipes coated with zinc to prevent rusting. This process enhances their durability and lifespan. They have been widely used in plumbing and construction for many years. According to industry reports, galvanized pipes can last up to 50 years when properly maintained. Their resistance to corrosion makes them suitable for water supply lines.

Despite their advantages, there are some downsides to consider. Over time, galvanized pipes can accumulate mineral deposits inside. This may restrict water flow and reduce efficiency. Additionally, older galvanized pipes may contain lead. A study from the American Water Works Association indicates that homeowners with such pipes might face health risks.

Installing galvanized pipes requires careful planning. Assess the environment to prevent future issues. Regular inspections are important to catch problems early. While they offer longevity, proper installation techniques are essential. Not every project may benefit from using them. Always weigh the pros and cons before making a decision.

When selecting galvanized pipes for your project, consider several key factors. The diameter of the pipe is crucial. A pipe too small will limit water flow. Conversely, a pipe that is too large can be cumbersome to install. Pay attention to the wall thickness, too. Thicker walls provide better durability but may add weight.

Corrosion resistance is another important aspect. While galvanized pipes are generally resistant to rust, they can still corrode over time. Regular inspection can help catch issues early. Think about the intended application as well. Some projects may require flexible pipes, prompting a reevaluation of your choices.

Installation ease varies among different types of galvanized pipes. Some require special tools. Even things like joint compatibility matter. A slight mismatch can lead to leaks. There’s also the question of fitting into existing systems. Compatibility can be tricky. Overall, careful consideration of these factors can make a significant difference in your project's success.

This chart presents the durability ratings of different galvanized pipe options that can be considered for your next project. Each rating is based on various factors including resistance to rust, strength, and expected lifespan. Choose wisely!

When selecting galvanized pipes for your next project, consider key features and benefits. Galvanized pipes have a zinc coating that protects against rust and corrosion. This coating increases the pipe's lifespan, making it ideal for various applications. They are often used in plumbing, HVAC systems, and for structural purposes.

Tip: Always check the pipe's diameter and thickness for your specific project requirements. A thicker pipe might be necessary for heavy-duty applications, while a standard diameter could work for lighter uses.

Another benefit is their availability. Galvanized pipes come in various sizes, making it easier to find the right fit. They are also relatively affordable, which can help stay within budget constraints. However, it’s essential to inspect them carefully before purchase.

Tip: Look for any signs of damage or corrosion. Choosing the wrong pipe can lead to costly repairs later. Don’t hesitate to ask for advice if unsure which option suits your needs best. This decision can greatly impact your overall project quality.

| Option | Diameter (inches) | Length (feet) | Weight (lbs) | Corrosion Resistance | Applications |

|---|---|---|---|---|---|

| Galvanized Pipe A | 1 | 10 | 3.5 | High | Plumbing, Construction |

| Galvanized Pipe B | 1.5 | 20 | 6 | Moderate | Agricultural Irrigation |

| Galvanized Pipe C | 2 | 15 | 9 | High | Construction, Fencing |

| Galvanized Pipe D | 2.5 | 30 | 12 | Very High | Marine, Outdoor Structures |

| Galvanized Pipe E | 3 | 25 | 15 | Moderate | Industrial, Plumbing |

| Galvanized Pipe F | 2 | 10 | 5 | High | Heating Systems |

| Galvanized Pipe G | 1.25 | 12 | 4 | Moderate | Gas Lines |

| Galvanized Pipe H | 1.75 | 20 | 8 | High | Water Supply |

| Galvanized Pipe I | 3.5 | 30 | 20 | Very High | Heavy Duty Framework |

| Galvanized Pipe J | 2 | 5 | 3 | High | Residential Projects |

When considering galvanized pipes, cost is a significant factor. Prices vary based on thickness, diameter, and the supplier. Expect to pay more for larger sizes or heavier gauges. However, the initial cost should not overshadow the long-term savings. Galvanized pipes resist corrosion, which means fewer replacements over time. This durability can lead to lower maintenance costs.

Durability is another critical aspect. Galvanized pipes can last several decades when properly installed. They are suitable for various applications, from residential plumbing to outdoor structures. Yet, improper installation can lead to leaks and failures. It's vital to assess the overall environment too. For example, pipes in humid conditions may exhibit rusting sooner than expected.

Application plays a pivotal role in the choice of galvanized pipes. Some projects require specific types of pipes, depending on the intended use. For example, pipes used in agricultural settings may need additional protection against harsh elements. Evaluating these factors can prevent unforeseen issues. Ultimately, finding the right balance between cost, durability, and application is essential for any project.

Galvanized pipes are durable, but they need care. Regular maintenance is essential. Inspect pipes for rust or corrosion every few months. Loose fittings can lead to leaks. A small leak can escalate, causing significant damage over time.

A study by the American Water Works Association found that maintenance can extend the life of pipes by up to 30%. Keeping pipes clear of debris is vital. If water flow slows, check for blockages. A simple cleaning can restore function. Imagine discovering a small blockage that leads to a larger issue due to neglect.

Temperature changes can stress pipes. Galvanized steel can expand and contract. This can cause joints to loosen. Tightening them periodically helps maintain integrity. It’s a small step that can prevent costly repairs. Remember, even small issues require prompt attention. Think about how easy it is to overlook minor wear while focusing on bigger projects.