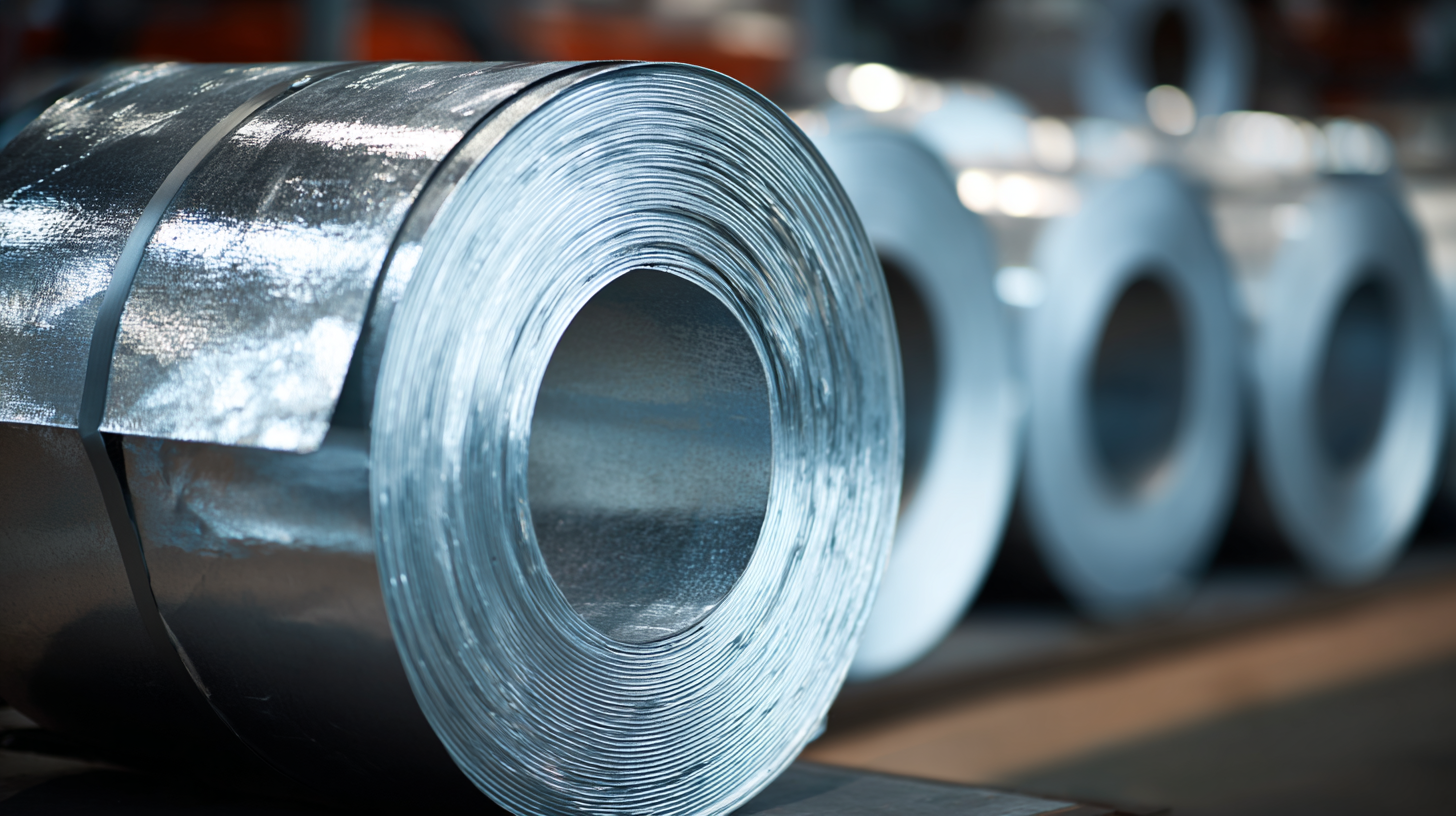

In the ever-evolving landscape of the steel industry, the significance of galvanized coil has emerged as a critical factor for global buyers seeking optimal durability and corrosion resistance in their applications. According to a recent market analysis report from ResearchAndMarkets, the global galvanized steel market is projected to reach USD 192.23 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 6.4% from 2020. This rapid growth underscores the increasing demand for galvanized coil, driven by the construction, automotive, and appliance sectors, where performance and longevity are paramount. As industries worldwide place greater emphasis on sustainability and quality, understanding the characteristics and manufacturing processes of the best galvanized coil will be essential for decision-makers looking to secure reliable and high-performing materials that stand the test of time.

When evaluating high-quality galvanized coils, several key characteristics define their suitability for global buyers. According to a report by MarketsandMarkets, the global galvanized steel market is projected to reach USD 237 billion by 2026, driven primarily by the increasing demand in automotive and construction applications.

High-quality galvanized coils typically feature a superior zinc coating, which enhances corrosion resistance. The G90 coating standard is commonly recognized, providing a thickness of 0.90 ounces per square foot, crucial for long-lasting performance in harsh environments.

Another critical characteristic is the mechanical properties of the steel substrate. The American Society for Testing and Materials (ASTM) specifications recommend certain tensile strength levels to ensure that the coils can withstand shaping and molding processes without failing. High-quality galvanized coils should also display minimal surface defects, such as scratches or scaling, which can negatively impact both aesthetics and functionality.

Reports indicate that coils adhering to these stringent criteria can lead to reduced warranty claims and higher customer satisfaction ratings, further underscoring their essential role in various industries.

The impact of zinc coating thickness on the lifespan and performance of galvanized coils cannot be understated, especially for global buyers seeking to optimize their investments. A thicker zinc coating is directly correlated with enhanced corrosion resistance, ensuring that the steel retains its integrity even in harsh environments. This is particularly critical for applications in construction and automotive industries, where exposure to moisture and chemicals can lead to rapid deterioration. Buyers should be aware that while a thicker coating may initially increase costs, the long-term savings on maintenance and replacement can be substantial.

Market trends indicate a growing demand for electro galvanized steel, with its market projected to expand significantly from USD 18.5 billion in 2024 to USD 27.2 billion by 2033. This growth highlights the increasing recognition of the advantages provided by electro galvanization, which offers finer control over coating thickness and uniformity. Consequently, manufacturers and suppliers must prioritize the quality of zinc coatings to meet the evolving demands of buyers who are looking for durable, high-performance products that will stand the test of time.

The galvanized coil market is undergoing significant transformations driven by various global trends. In 2023, the global stainless steel market reached a value of $206.91 billion, with expectations to grow to $216.16 billion by 2024 and to $320.37 billion by 2032. This growth trajectory demonstrates the rising demand for high-quality materials, including galvanized coils, which are crucial for industries such as automotive, construction, and electrical applications.

Recent industry reports have highlighted key market demand trends, particularly in regions like Mexico and Gabon, where fluctuations in import volumes are influenced by domestic needs and international trade policies. As global economic conditions fluctuate and trade protectionism rises, it becomes evident that buyers should adopt a proactive approach in sourcing galvanized coils to mitigate risks.

**Tips:**

1. Understand the regional demand by staying updated with international trade policies that might affect supply chains.

2. Consider the quality and type of galvanized coils best suited to your industry needs to ensure longevity and performance.

3. Keep an eye on market trends and forecasts to make informed purchasing decisions that align with growth projections in the steel industry.

Understanding the comparative costs of galvanized coils in global markets is crucial for buyers navigating the complexities of the coated steel industry. Recent trends indicate a significant decline in the steel price index, which dropped by 21% year-on-year in 2023. This persistent downtrend, evident in hot rolled coils and hot dipped galvanized prices, is reshaping pricing strategies and market approaches for buyers worldwide. The fluctuations in raw material prices, driven by trade tensions and economic indicators, further complicate the pricing landscape.

Additionally, the coated steel market, which includes products like galvanized steel and pre-painted steel, is projected to experience growth, spurred by industrial demand and infrastructural developments. Buyers must consider factors like coating methods and the economic context influencing supply chains. As analysts forecast conditions for the coming years, understanding these pricing factors becomes essential for making informed purchasing decisions in a competitive market. The evolving dynamics of steel and coated products highlight the importance of strategic procurement in response to global economic shifts.

| Region | Average Price per Ton (USD) | Main Applications | Key Pricing Factors |

|---|---|---|---|

| North America | $800 | Construction, Automotive | Supply chain costs, tariffs |

| Europe | $750 | Building, Manufacturing | Raw material prices, demand fluctuations |

| Asia Pacific | $700 | Infrastructure, Electronics | Market demand, exchange rates |

| Middle East | $780 | Oil & Gas, Construction | Logistics costs, geopolitical factors |

| Latin America | $720 | Agriculture, Automotive | Economic conditions, transportation costs |

The future of galvanized steel in construction and manufacturing is heavily influenced by sustainability and recycling practices. As industries shift towards eco-friendly operations, galvanized steel stands out due to its durability and corrosion resistance. These properties not only extend the lifespan of structures but also minimize material waste, making it an attractive option for builders and manufacturers committed to reducing their environmental impact.

When selecting galvanized coils, buyers should consider the source of raw materials used in their production. Opting for suppliers that prioritize recycled content can significantly enhance sustainability efforts. Additionally, seeking out products that are easy to recycle at the end of their lifecycle helps ensure that galvanized steel contributes to a circular economy.

Investing in advanced manufacturing processes that reduce energy consumption is another crucial tip. Buyers should look for companies that utilize innovative techniques, as these can lead to lower carbon emissions and a smaller overall environmental footprint. By focusing on sustainable practices and responsible sourcing, global buyers can play a pivotal role in promoting a greener future for the galvanized steel industry.