In the world of construction materials, Galvalume Coil is gaining notable attention. Experts emphasize its advantages. John Smith, a seasoned industry specialist, once stated, “Galvalume Coil combines durability with cost-effectiveness.” This highlights why it stands out among other materials.

Choosing the right Galvalume Coil can be challenging. With numerous products available, how do you know which ones to trust? Understanding your specific needs is crucial. For instance, consider the environment where the material will be used. Exposure to harsh weather can determine the type of Galvalume Coil you need.

Manufacturers offer various specifications. However, not all products live up to expectations. Some coils may rust or lose their finish sooner than advertised. It's essential to look beyond surface claims and seek reliable reviews. This ensures you make an informed decision that suits your project requirements.

When it comes to selecting Galvalume coil products, corrosion resistance is a critical factor. Galvalume is known for its durability, but not all options are created equal. Products vary widely in their performance against rust and corrosion. Therefore, it's essential to choose wisely based on specific needs.

One good approach is to look for products with high corrosion resistance ratings. These ratings often stem from extensive testing in various environments. For example, some coils maintain strength even in high humidity. Yet, not every product performs the same way, especially in harsh conditions. It's valuable to identify what environments the coils will face.

Many users overlook long-term exposure in coastal regions. The salty air can quickly deteriorate lower-quality coils. Regular maintenance can prolong lifespan, but it's wise to choose a product designed for tough climates. Ultimately, the right Galvalume coil could save you time and money. A well-made product pays off in the long run, minimizing unexpected repairs or replacements.

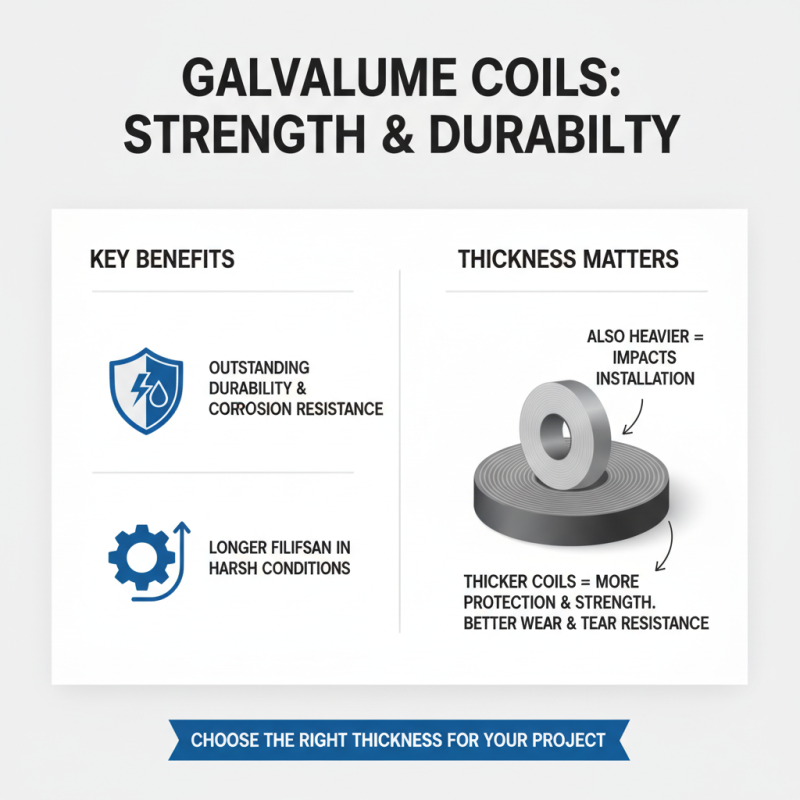

Galvalume coils are known for their outstanding durability and resistance to corrosion. When considering thickness, it’s vital to recognize how it influences the coil's strength. Thicker coils generally provide more protection against wear and tear. They often perform better in challenging weather conditions. However, thicker options can also be heavier, impacting installation processes.

Examining the durability of different thicknesses reveals interesting insights. A lighter gauge may save on initial costs but could lead to increased maintenance needs over time. Indicatively, some thinner products may require more frequent replacements. This raises questions about long-term investment. Choosing the right thickness means finding a balance between weight and performance.

The overall quality can vary based on manufacturing processes. Not all coils labeled as Galvalume will offer the same durability. Some may show wear sooner than expected. It's essential to research and ask questions. The best choice aligns with specific environmental needs and project requirements. Understanding these factors can help consumers make informed decisions.

The coating type of galvalume coils plays a critical role in their longevity. Different coatings offer varying levels of protection against rust and corrosion. Some coatings use a combination of aluminum and zinc. This combination often shows superior resistance to harsh weather conditions.

However, not all coatings are created equal, leading to different performance results.

Moreover, environmental factors greatly influence the durability of galvalume products. High humidity or coastal environments can accelerate corrosion. In those cases, a thicker coating may be necessary. Yet, using thicker coatings can add to the overall weight and cost of the product. These choices often lead to a balancing act between performance and affordability.

It's essential to assess your specific needs before selecting a galvalume coil. The right coating can enhance lifespan but may come with trade-offs. Be mindful when making a decision. Reflect on the long-term impacts on maintenance and replacement costs. A poor choice could lead to increased expenses down the line. Each application has its nuances, and sometimes, a one-size-fits-all approach falls short.

The market for Galvalume coil products in 2023 is witnessing significant trends. Demand has increased due to the construction industry's recovery. According to a recent industry report, the global Galvalume market is projected to grow at a CAGR of 5.2% from 2023 to 2028. This growth is driven by increased applications in roofing and siding.

Pricing trends show a steady increase as well. Currently, the price per ton of Galvalume coil ranges from $1,200 to $1,500. Factors influencing these prices include raw material costs and global supply chain disruptions. Simple shifts in demand can cause noticeable price fluctuations. Buyers should remain vigilant regarding these trends.

**Tip:** Always investigate regional supply chains. A local supplier may offer better prices.

As the market evolves, some manufacturers struggle to keep pace. Quality control remains a critical issue for many. Instances of subpar products have been noted. Reliability should never be compromised in your material choices.

**Tip:** Consider conducting quality audits. They can ensure the longevity of your purchase.

Staying informed about these trends is essential for any business relying on Galvalume products. Understanding pricing and demand will facilitate better purchasing decisions. Be proactive in adapting to market changes.

When selecting the right Galvalume coil for your project, several essential factors come into play. Galvalume steel consists of a zinc-aluminum alloy, providing excellent corrosion resistance. According to industry reports, the coating can increase the lifespan of steel by up to 50%. It's crucial to consider the coating thickness. A thicker coating offers better protection but may be less flexible during fabrication.

Another factor is the substrate quality. Not all steel is created equal. High-quality substrate improves the performance of the Galvalume coil. Check for the ASTM specifications that ensure durability and consistency. Experienced contractors recommend a minimum yield strength of 50 ksi for structural applications. It's often overlooked, yet essential for long-term performance.

Aesthetics can also impact your choice. Different finishes and colors can be applied to Galvalume products. While many prefer the sleek appearance, one should consider maintenance. A reflective surface may look great initially but could show dirt and stains more prominently. Balance aesthetics with practicality in mind.