In the world of electrical applications, materials play a crucial role in determining efficiency, safety, and durability. Among the various options available, copper strips have emerged as a preferred choice for many professionals due to their remarkable properties. Copper strips, known for their excellent conductivity, strength, and resistance to corrosion, offer a range of benefits that enhance the performance of electrical systems.

The versatility of copper strips extends beyond simple electrical wiring; they find application in grounding, shielding, and even in advanced electronic devices. Their unique characteristics make them indispensable in industries that require reliable and safe electrical connections. By exploiting the advantages of copper strips, manufacturers and engineers can ensure not only the longevity of their products but also the safety and reliability of their electrical systems. In the following sections, we will explore the top 10 benefits of using copper strips in electrical applications and beyond, shedding light on why this material continues to be a preferred choice in a range of applications.

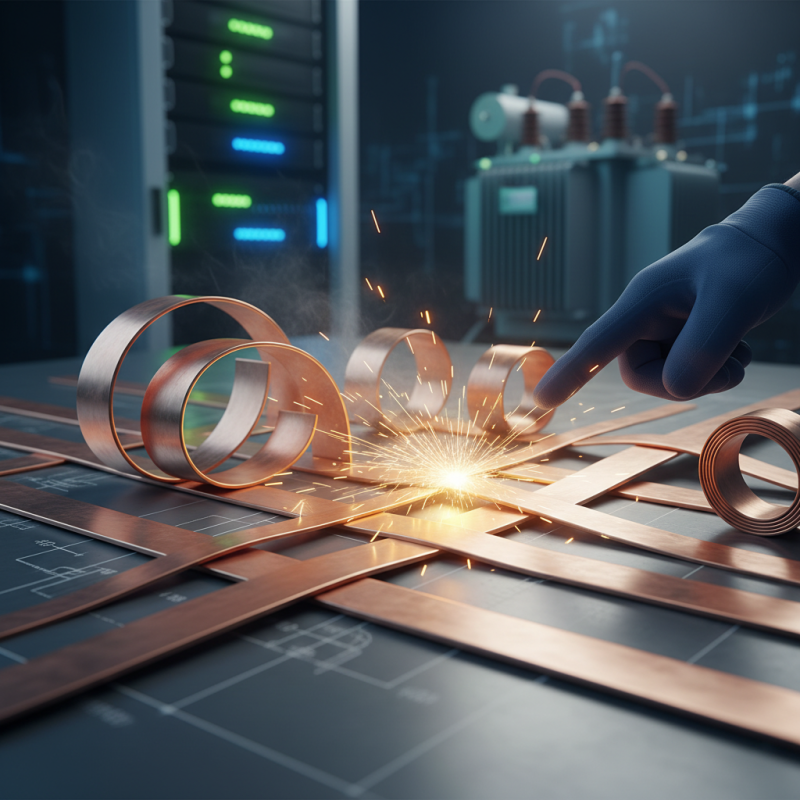

Copper strips are widely recognized for their exceptional electrical conductivity, making them an indispensable material in various electrical applications. The unique atomic structure of copper allows for a high rate of electron flow, resulting in minimal energy loss during transmission. This metal's low resistivity enables it to efficiently conduct electricity, which is crucial for applications ranging from power generation to telecommunications. Consequently, the use of copper strips can significantly enhance performance in electrical circuits, ensuring reliable energy distribution and reducing operational costs.

In addition to electrical conductivity, copper strips offer excellent thermal conductivity, which is beneficial in applications like heat sinks and transformers. The ability to dissipate heat effectively helps prevent overheating in electrical components, thereby improving their longevity and efficiency. Copper's malleability also allows for easy fabrication into various shapes and sizes, further adding to its versatility in electrical systems. Whether utilized in circuit boards, connectors, or grounding systems, copper strips are vital for achieving optimal performance and ensuring the safe operation of electrical devices.

Copper strips are widely recognized for their exceptional durability and corrosion resistance, making them an ideal choice for various electrical applications. Unlike other metal options, copper naturally forms a protective patina when exposed to atmospheric conditions, which further enhances its resistance to corrosion. This quality ensures a longer lifespan of electrical components, reducing the need for frequent replacements and maintenance, ultimately leading to cost savings for businesses.

When using copper strips in electrical applications, it is essential to consider some tips for maximizing their benefits. First, ensure proper installation techniques are followed to avoid mechanical stress that could compromise the integrity of the copper. Second, regular visual inspections can help identify any signs of wear or damage early on, allowing for timely interventions. Lastly, maintaining a clean environment around copper installations minimizes the risk of contaminants that could trigger oxidation.

Furthermore, the electrical conductivity of copper is unparalleled, which contributes to the efficiency of electrical systems. By utilizing copper strips, engineers can design systems that not only perform reliably under heavy loads but also exhibit minimal energy losses. Thus, leveraging the durability and corrosion resistance of copper strips can significantly enhance the overall functionality of electrical applications while contributing to sustainability goals through reduced resource consumption.

Copper strips are increasingly recognized for their pivotal role in enhancing energy efficiency and driving cost savings in various electrical applications. According to a report by the International Copper Association, the use of copper in electrical systems can improve conductivity by up to 60% compared to aluminum, leading to lower energy losses. This improved efficiency not only minimizes electricity consumption but also contributes to a more sustainable and environmentally friendly operation.

Implementing copper strips in electrical wiring and components ensures less energy wastage and reduced heat buildup. The U.S. Department of Energy notes that systems utilizing copper can lead to energy savings of up to 30% in specific applications. As buildings and industries strive to meet energy efficiency standards, copper strips become an integral part of the solution, helping to comply with regulations while keeping operational costs low.

Tips: When planning an electrical project, consider choosing copper strips to optimize energy usage. Perform a lifecycle cost analysis to understand the long-term savings associated with initial investments in copper materials. Additionally, ensure proper installation to maximize the benefits of conductivity and efficiency throughout the system.

| Benefit | Description | Energy Efficiency Improvement (%) | Cost Savings ($ per Year) |

|---|---|---|---|

| Superior Conductivity | Copper strips provide excellent electrical conductivity, reducing energy loss. | 15% | $200 |

| Durability | Copper is resistant to corrosion and wear, leading to longevity in applications. | N/A | $150 |

| Cost-Effectiveness | Long-term savings on maintenance and replacements enhance cost-effectiveness. | N/A | $300 |

| Versatility | Can be used in a variety of electrical applications from connectors to grounding. | N/A | $100 |

| Heat Resistance | Excellent thermal conductivity helps manage heat dissipation in electrical systems. | 20% | $250 |

| Sustainability | Recyclable properties make copper a sustainable choice for electrical applications. | N/A | $75 |

| Low Electromagnetic Interference | Copper strips reduce electromagnetic interference, enhancing signal integrity. | 30% | $400 |

| Easy Installation | Lightweight and flexible, making installation easier and faster. | N/A | $120 |

| Aesthetic Appeal | Copper has a visually appealing finish, suitable for decorative applications. | N/A | $90 |

| Improved Safety | Reduces overheating and electrical failures, increasing the overall safety of installations. | N/A | $300 |

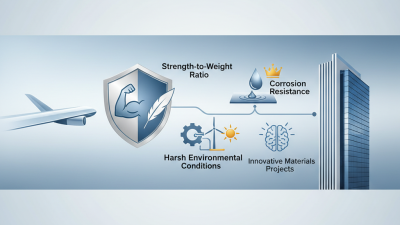

Copper strips are renowned for their versatility, making them indispensable in a myriad of industries beyond their primary use in electrical applications. In the construction sector, copper strips are used for roofing and architectural elements due to their excellent corrosion resistance and aesthetic appeal. Their natural malleability allows architects and builders to create intricate designs, which not only enhances the visual aspect of structures but also contributes to long-term durability.

In the electronic industry, copper strips play a critical role in communication systems and power distribution. The high conductivity of copper ensures efficient energy transfer, reducing power loss in both residential and industrial applications. Additionally, copper’s non-magnetic properties make it ideal for use in sensitive electronic components like circuit boards, where maintaining signal integrity is crucial. From HVAC systems to industrial machinery, copper strips offer reliable performance and longevity, proving their adaptability across a broad range of applications.

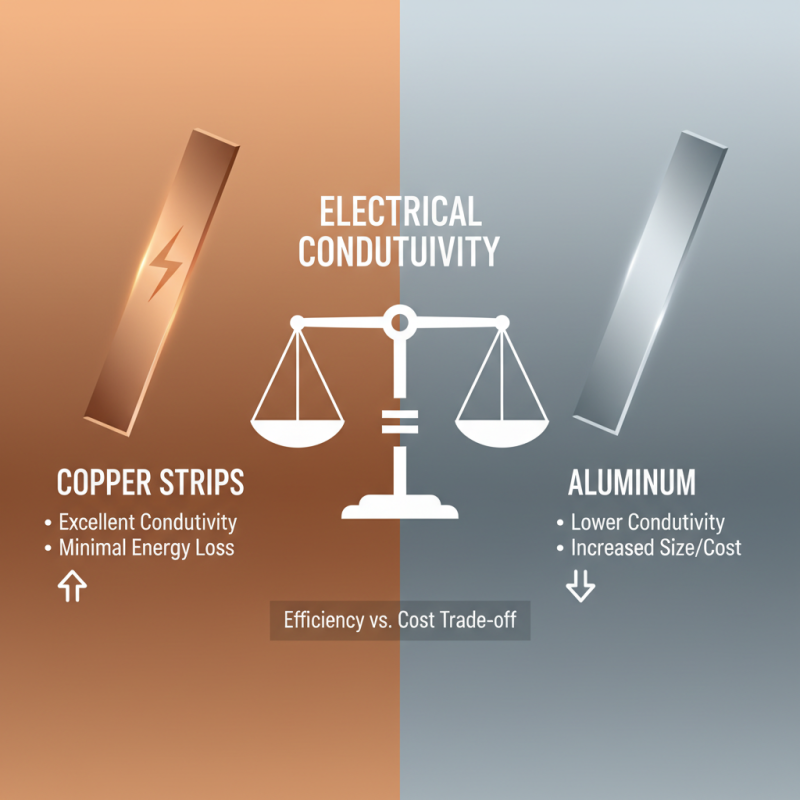

When comparing copper strips with alternative materials used in electrical applications, one of the most significant factors is electrical conductivity. Copper is renowned for its excellent conductivity, allowing it to efficiently transmit electrical currents with minimal energy loss. This characteristic is crucial in power distribution and electronic components, where performance and efficiency are paramount. In contrast, materials such as aluminum, while lighter and less expensive, typically exhibit lower conductivity and may require larger gauges to achieve equivalent performance, potentially leading to increased costs in terms of both material and installation.

Another important aspect to consider is the corrosion resistance of copper compared to other metals. Copper naturally forms a protective oxide layer that helps prevent further corrosion, making it ideal for use in both indoor and outdoor environments. This durability extends the lifespan of electrical components, reducing maintenance costs and enhancing reliability. Alternative materials, like steel or certain alloys, can be prone to rusting and deterioration, particularly when exposed to moisture or corrosive elements, ultimately compromising their functionality and increasing the need for replacements. Hence, while alternatives may offer initial cost benefits, the long-term advantages of copper strips in terms of longevity and efficiency make them a superior choice for many electrical applications.