In the realm of construction and manufacturing, the choice of materials can significantly impact the outcome of various projects. One such material that has garnered attention for its versatility and strength is aluminum plate. According to industry expert Dr. Michael Thompson, "The unique properties of aluminum plate make it an ideal choice for a multitude of applications, from aerospace to architectural designs." His insight highlights the growing realization among engineers and designers about the numerous benefits that aluminum plates bring to the table.

Aluminum plates are not only lightweight but also boast impressive strength-to-weight ratios, making them a preferred option in situations where every ounce counts. Their resistance to corrosion and ability to withstand harsh environmental conditions further enhance their suitability for both indoor and outdoor applications. As industries evolve and the demand for innovative materials increases, understanding the top benefits of using aluminum plate becomes crucial for professionals aiming to optimize their projects and achieve lasting results.

Aluminum plates are increasingly favored in construction and engineering projects due to their impressive strength-to-weight ratio and corrosion resistance. According to a report by the Aluminum Association, aluminum structures can save up to 30% in weight when compared to steel alternatives, allowing for simpler installations and reduced overall structural weight. This is particularly advantageous in large-scale engineering projects, such as bridges and high-rise buildings, where both structural integrity and material savings are critical.

In addition to their weight advantages, aluminum plates exhibit significant durability and longevity. The Metal Construction Association reports that aluminum’s natural resistance to corrosion can extend the lifespan of infrastructure projects, reducing maintenance costs over time. Furthermore, studies show that buildings utilizing aluminum components often see a decrease in energy costs due to enhanced thermal efficiency. This makes aluminum not only a smart choice for structural applications but also a sustainable option that is increasingly important in modern construction practices.

The lightweight advantage of aluminum plates makes them an ideal choice for a wide range of projects and applications, from construction to transportation. Their low density means that they can provide significant weight savings compared to other materials, translating into easier handling and reduced transportation costs. This feature is particularly beneficial in industries where minimizing weight is crucial, such as

aerospace and automotive sectors, where every gram counts toward fuel efficiency.

In addition to their lightweight properties, aluminum plates exhibit excellent strength-to-weight ratios, ensuring that projects maintain structural integrity without the excess weight. This advantage allows designers and engineers to create more innovative solutions without compromising durability. Moreover, aluminum’s resistance to corrosion enhances its lifespan, making it a cost-effective choice for long-term applications.

Tips for utilizing aluminum plates effectively include:

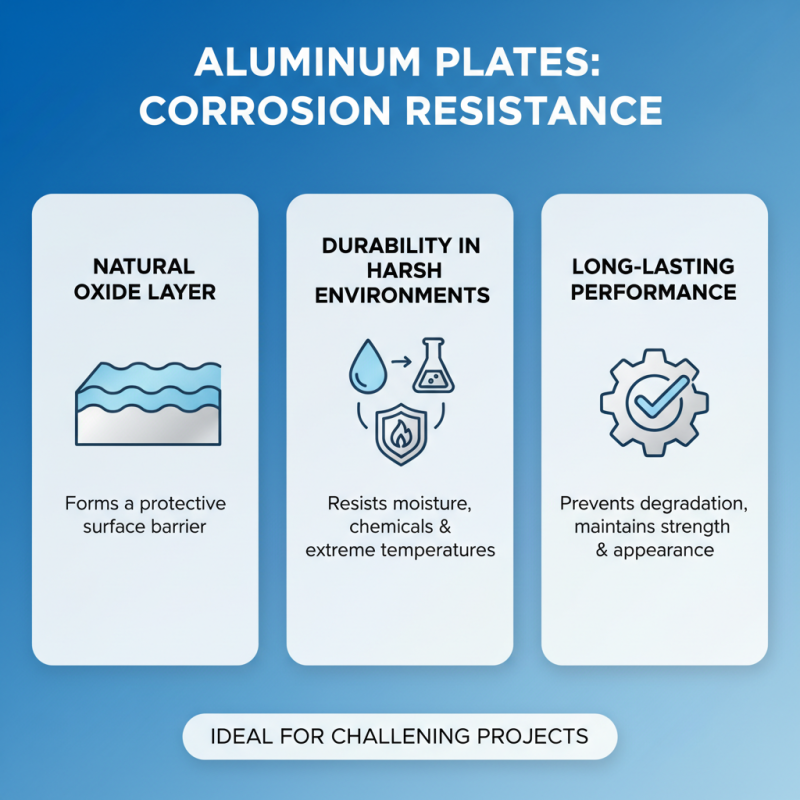

Aluminum plates are renowned for their exceptional corrosion resistance, making them an ideal choice for a variety of projects and applications, especially in challenging environments. The naturally occurring oxide layer that forms on the surface of aluminum provides a protective barrier, preventing oxidation and subsequent degradation. This property is crucial in situations where materials are exposed to moisture, chemicals, or extreme temperatures, ensuring that the aluminum plate remains structurally sound and visually appealing over time.

Moreover, the durability of aluminum plates extends beyond their resistance to corrosion. Their ability to withstand harsh conditions without losing integrity enhances their application in industries such as construction, aerospace, and marine. For instance, structures that face repeated exposure to saltwater benefit substantially from aluminum plates, which do not rust like steel or iron counterparts, thereby reducing maintenance costs and increasing longevity. This combination of lightweight characteristics and robust durability makes aluminum plates a smart investment for engineers and designers aiming to deliver reliable and lasting solutions.

Aluminum plates are becoming increasingly popular in various manufacturing and fabrication processes due to their remarkable versatility. They can be easily machined, welded, and formed, making them suitable for a wide range of applications. The lightweight nature of aluminum combined with its strength enables manufacturers to create products that are both durable and easy to handle. This makes aluminum plates ideal for industries such as aerospace, automotive, and construction, where performance and weight are critical factors.

Furthermore, aluminum plates can be treated with different finishes that enhance their aesthetic appeal and functional properties. They can be anodized, painted, or coated to resist corrosion, thereby extending their lifespan and maintaining their appearance in harsh environments. This adaptability allows designers and engineers to integrate aluminum plates into their projects seamlessly, whether for structural components or decorative elements. The ability to customize aluminum plates to meet specific project requirements is a significant advantage that can lead to innovative solutions in design and manufacturing.

When considering materials for your projects, aluminum plate stands out as a cost-effective choice that promises long-term savings. The initial investment in aluminum may be slightly higher than some alternatives, but its durability and low maintenance requirements quickly offset this cost. Aluminum plates are resistant to corrosion, which means they require less frequent replacement and repair compared to other materials. This leads to significant savings over the life cycle of the project, as the need for ongoing upkeep is minimized.

Moreover, the lightweight nature of aluminum plates contributes to further economic advantages. They are easier to handle and transport, which can reduce labor costs and logistics expenses. In applications where efficiency is paramount, such as in construction or manufacturing, this reduction in weight translates into lower energy consumption during transportation and installation. Ultimately, using aluminum plate not only enhances the quality of the final product but also ensures that budgetary resources are utilized effectively, allowing for reinvestment into other critical areas of the project.