In the construction and manufacturing sectors, the use of Cold Rolled Sheet has surged in recent years, largely due to its superior mechanical properties and aesthetic appeal. According to a report by MarketsandMarkets, the global cold rolled steel market is projected to reach USD 250 billion by 2025, growing at a CAGR of 5.3% from 2020. This remarkable growth underscores the increasing reliance on Cold Rolled Sheet for projects requiring precision and durability.

Expert in Metallurgy, Dr. Emily Roberts, highlights the advantages of Cold Rolled Sheets by stating, “The consistency in thickness and enhanced surface finish offered by cold rolling technology can significantly elevate the performance of structural components.” This is particularly relevant in applications such as automotive manufacturing, metal fabrication, and home appliances, where both strength and aesthetics play a critical role. As industries continue to evolve, investing in Cold Rolled Sheet not only ensures longevity and reliability in project outcomes but also fosters innovation through improved design capabilities.

Embracing Cold Rolled Sheet in your next project can lead to substantial benefits, ranging from enhanced mechanical properties to cost-effectiveness, making it an undeniable choice for professionals aiming to deliver high-quality results.

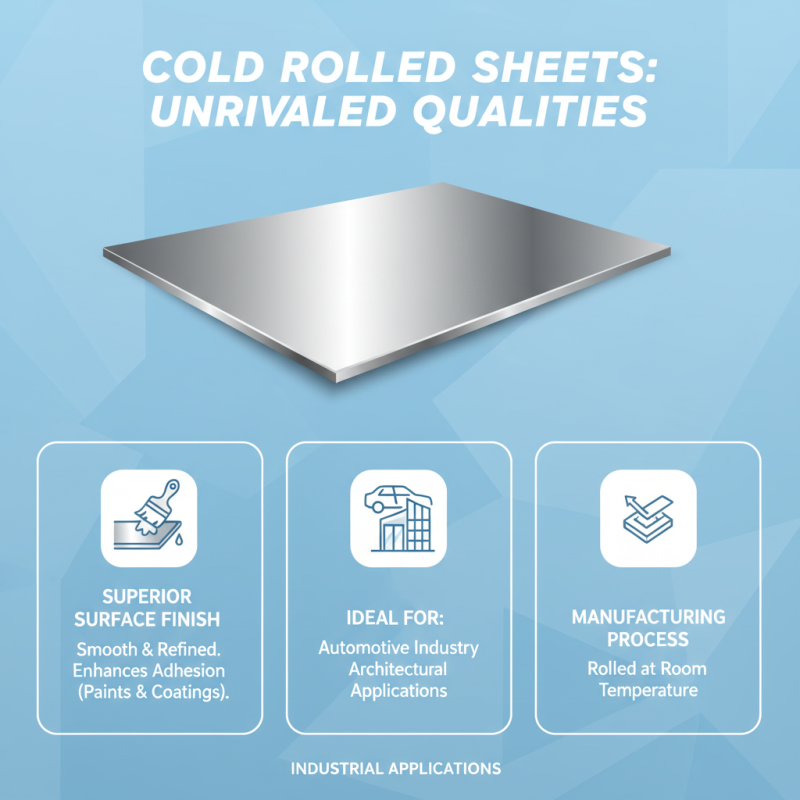

Cold rolled sheets are renowned for their unique characteristics, which make them an ideal choice for various industrial applications. One of the primary attributes of cold rolled sheets is their exceptional surface finish. The manufacturing process involves rolling the metal at room temperature, which results in a smooth and refined surface. This quality not only enhances aesthetic appeal but also allows for better adhesion in paint and coatings, making cold rolled sheets a preferred option in architectural and automotive industries.

Another key characteristic of cold rolled sheets is their increased strength and precision. The cold rolling process leads to a denser metal structure, providing higher tensile strength compared to hot rolled alternatives. This strength is crucial for applications where structural integrity is paramount. Additionally, cold rolled sheets are available in tighter tolerances, meaning they can be produced to specific dimensions with minimal variation, allowing for greater accuracy in manufacturing processes and reduced waste during production. This combination of strength and precision makes cold rolled sheets a go-to material for engineers and designers alike.

Cold rolled sheets are a preferred material across various industries due to their exceptional characteristics and versatility. The precision in thickness and surface finish achieved through the cold rolling process makes these sheets ideal for applications in automotive manufacturing, construction, and appliance fabrication. In the automotive sector, manufacturers benefit from the enhanced strength and formability of cold rolled sheets, which are crucial for producing lightweight yet durable components that optimize fuel efficiency and safety.

When working with cold rolled sheets, proper handling and storage are essential to maintain their integrity. Here are some tips: always store the sheets in a dry environment to prevent rusting, and use protective gloves while handling to avoid any skin oils damaging the surface finish. Additionally, when cutting or shaping the sheets, ensure that the tools being used are sharp and appropriate for metalworking to achieve clean edges and prevent deformation.

Moreover, cold rolled sheets offer superior weldability, which is a significant advantage in various industries. This property allows for stronger joints and reduces the likelihood of defects during the assembly process. Whether in machinery, furniture, or structural applications, choosing cold rolled sheets can lead to improved performance and longevity of the final products. Remember to consider the specific grade and thickness based on your project's requirements to maximize the benefits of this versatile material.

| Industry | Benefits | Applications |

|---|---|---|

| Automotive | High strength, improved surface finish | Chassis components, body panels |

| Construction | Greater dimensional accuracy, less waste | Structural frames, roofing materials |

| Manufacturing | Versatility, cost-effectiveness | Machine parts, tooling plates |

| Aerospace | Weight savings, enhanced performance | Wing structures, fuselage components |

| Electronics | High purity, fine tolerances | Circuit boards, connector terminals |

Cold rolled sheets and hot rolled sheets serve as fundamental materials in various industries, but their distinct manufacturing processes result in notable differences that affect their application. Cold rolled sheets undergo a refining process at room temperature, which enhances their surface finish and dimensional tolerances. According to a report by the Steel Manufacturers Association, cold rolled sheets have a tighter thickness tolerance of approximately ±0.02 mm, compared to hot rolled sheets, which can vary by ±0.5 mm. This precision makes cold rolled sheets the preferred choice for applications requiring intricate detailing and smoother finishes, such as in automotive parts and appliances.

Moreover, the mechanical properties of cold rolled sheets generally surpass those of hot rolled sheets. The cold reduction in thickness results in an increase in yield strength, often cited to be up to 20% higher than that of hot rolled sheets. This improved strength translates to enhanced durability and performance in demanding environments. A study by the American Iron and Steel Institute indicates that cold rolled sheets are also less prone to surface defects, making them ideal for industries focused on aesthetics and quality. With their combination of precision and performance, cold rolled sheets offer significant advantages for projects demanding reliability and a polished appearance.

Cold rolled sheets have become an essential material in various construction and manufacturing applications due to their superior characteristics and versatility. In the construction industry, these sheets are commonly used for structural purposes, such as framing, reinforcing beams, and providing support for walls. Their increased strength and improved surface finish make them ideal for high-stress applications, where durability and aesthetic appeal are paramount. Moreover, cold rolled sheets can be easily cut and shaped, allowing for precise fabrication and assembly, which enhances the efficiency of construction processes.

In manufacturing, cold rolled sheets are widely utilized in the production of various components, including automotive parts, appliances, and machinery. The excellent dimensional accuracy and surface quality of these sheets facilitate high levels of precision in manufacturing operations. Additionally, their ability to withstand elevated temperatures and pressures makes them suitable for a broad range of industrial applications. As manufacturers continue to seek cost-effective and reliable materials, cold rolled sheets stand out as a preferred choice, supporting the development of innovative products across diverse sectors.

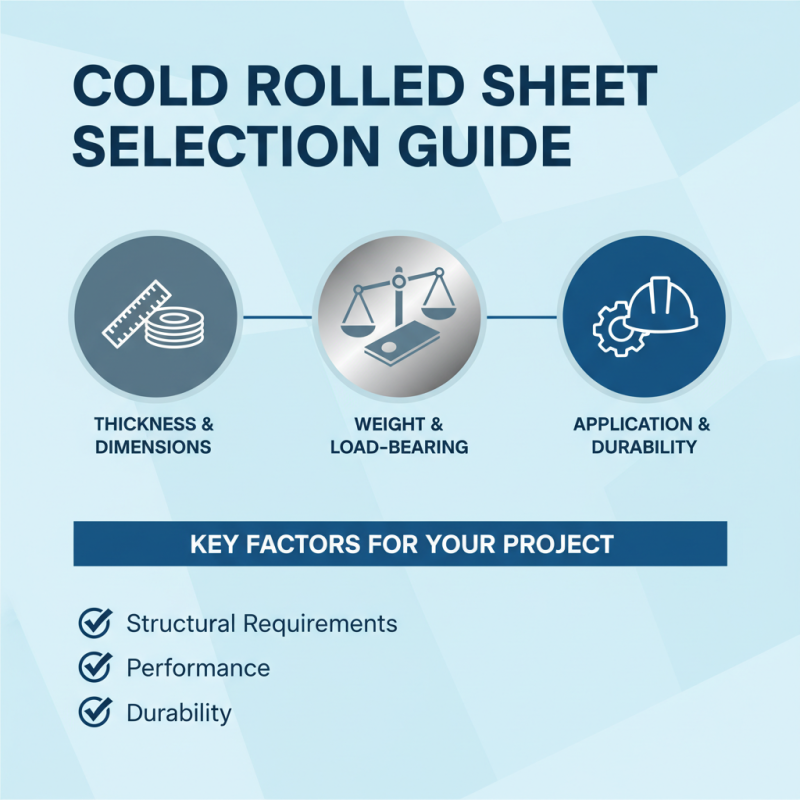

When selecting cold rolled sheets for your project, several critical factors should be taken into account. First, understanding the desired thickness and dimensions of the sheets is essential, as these specifications will directly influence the sheet's application and performance. Cold rolled sheets generally come in various thicknesses, and choosing the right one helps ensure that the final product meets structural requirements and offers durability. Additionally, assessing the weight of the sheets is important, especially for applications where load-bearing capabilities are crucial.

Another important factor is the finish of the cold rolled sheets. The surface finish can affect both aesthetics and functionality; for example, a smoother finish may be ideal for projects requiring a polished look, while a rougher texture might be better for applications needing better adhesion or grip. Furthermore, it's important to consider the material's mechanical properties, such as yield strength and tensile strength, which can significantly impact the sheet's performance in different environments. Evaluating these factors will help you choose the most suitable cold rolled sheets for your specific project needs.