In the ever-evolving landscape of material selection for construction and manufacturing, aluminum plate stands out as a versatile and efficient option. According to John Smith, a leading expert in metallurgical engineering, “Aluminum plates offer a unique combination of strength and lightweight characteristics, making them ideal for various applications.” This statement encapsulates the core advantages of aluminum plates, setting the stage for their increasing popularity across different industries.

Aluminum plates are lauded for their durability, corrosion resistance, and ease of fabrication, making them a top choice for projects ranging from aerospace components to architectural designs. Their inherent properties not only enhance performance but also contribute to sustainability efforts, as aluminum is fully recyclable. As businesses seek to innovate while adhering to eco-friendly practices, the use of aluminum plate has become a significant trend.

Aluminum plates are lauded for their durability, corrosion resistance, and ease of fabrication, making them a top choice for projects ranging from aerospace components to architectural designs. Their inherent properties not only enhance performance but also contribute to sustainability efforts, as aluminum is fully recyclable. As businesses seek to innovate while adhering to eco-friendly practices, the use of aluminum plate has become a significant trend.

Furthermore, understanding the specific benefits and applications of aluminum plates can empower stakeholders to make informed decisions in their projects. Whether you are an engineer, architect, or manufacturer, recognizing why aluminum plate is the smart choice can lead to successful outcomes and efficient resource utilization. With the insights from experts like John Smith, the potential of aluminum plates can be realized in a variety of applications, ensuring that they remain a preferred material for future ventures.

Aluminum plates are increasingly favored in construction and manufacturing due to their exceptional strength-to-weight ratio, corrosion resistance, and versatility. According to SMM statistics from May 2025, China produced 1.151 million metric tons of aluminum plates, sheets, and strips, highlighting the significant demand for these materials in various applications. This growth reflects the industry's recognition of aluminum's advantages, particularly in sectors that require lightweight yet durable materials for structural applications.

The North American aluminum market is also poised for substantial growth, with market analyses projecting it to expand significantly by 2032. With aluminum flat products valued at approximately USD 70.7 billion in 2025, expected to reach USD 110.9 billion by 2035, aluminum plates form a crucial component of this market. These products are increasingly integrated into building facades, roofing, and manufacturing processes, underscoring the material's vital role in modern construction and manufacturing practices. As industries continue to seek efficient and sustainable solutions, the demand for aluminum plates is likely to surge, making them an ideal choice for future projects.

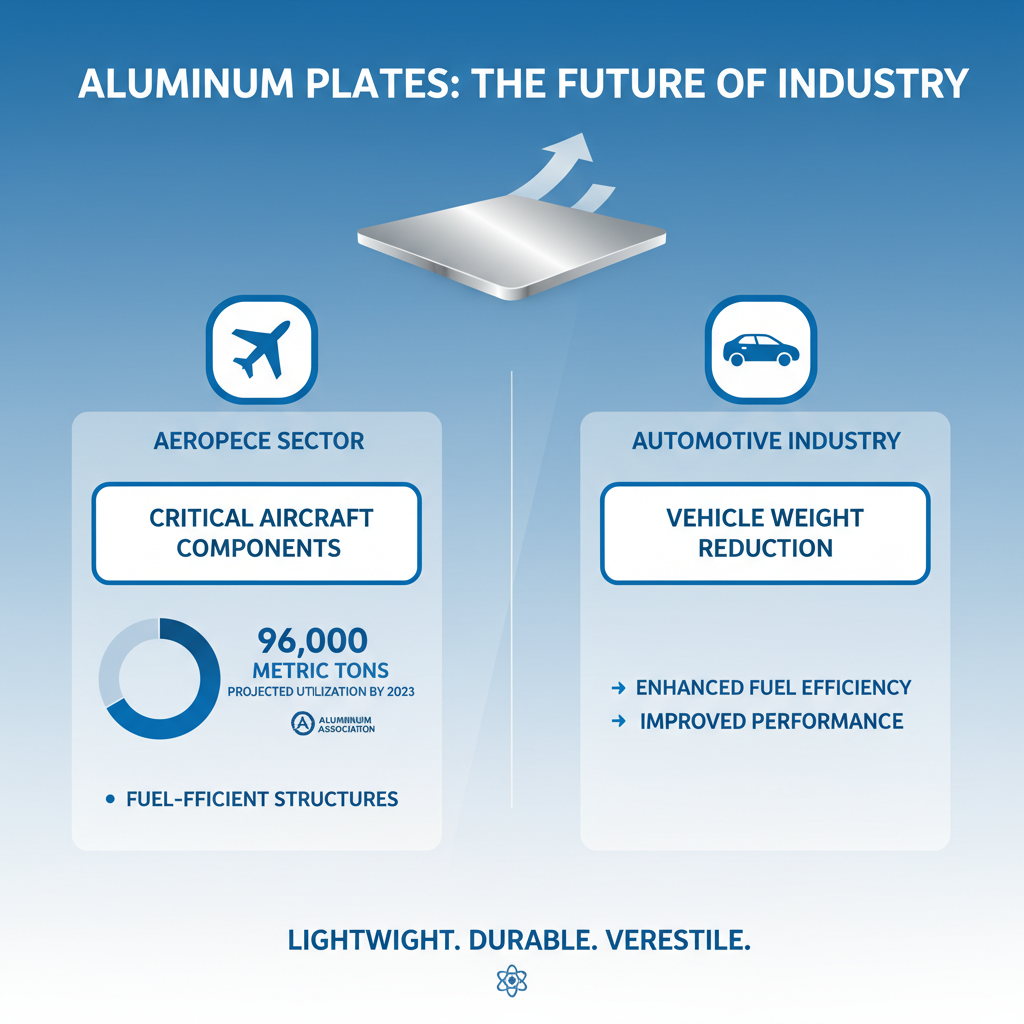

Aluminum plates are increasingly becoming a preferred material across various industries due to their combination of lightweight characteristics, durability, and versatility. In the aerospace sector, for instance, aluminum plates are essential for constructing critical aircraft components. According to the Aluminum Association, the aerospace industry is projected to utilize about 96,000 metric tons of aluminum in 2023 alone, highlighting its pervasive use in manufacturing fuel-efficient structures and parts. This trend is mirrored in the automotive industry, where lightweight aluminum plates contribute to vehicle weight reduction, thereby enhancing fuel efficiency and performance.

In construction, aluminum plates cater to diverse applications ranging from façades to roofing and structural supports. Recent studies indicate that the global aluminum plates market is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2020 to 2027, driven by demand for innovative building materials. Aluminum's corrosion resistance and aesthetic appeal make it a favorite for modern architectural designs, enabling energy-efficient buildings that meet contemporary sustainability standards.

Industries such as marine, electronics, and packaging also leverage aluminum plates for their unique properties, ensuring that this metal remains integral to a myriad of applications.

Aluminum plates are increasingly becoming a preferred material in a variety of industries due to their unique characteristics. The lightweight nature of aluminum makes it ideal for applications that demand high strength-to-weight ratios. For instance, in the automotive sector, there is a clear trend towards lightweight materials to enhance fuel efficiency and reduce emissions. Recent forecasts indicate that the aluminum extrusion market is expected to grow significantly, with a projected value of $44.7 million by 2025 and a compound annual growth rate of 4.4% until 2033.

In addition to their lightweight properties, aluminum plates are known for their excellent corrosion resistance, making them suitable for a wide range of environments, from marine applications to architectural elements. This inherent resistance to rust and wear ensures longevity and reduces the need for frequent maintenance. As noted in the industry reports, the shift towards more sustainable materials is further driving the adoption of aluminum in various fields.

Tip: When selecting materials for your project, consider the specific requirements such as weight restrictions, environmental exposure, and ease of fabrication. Aluminum plates can often meet these needs effectively while offering a combination of durability and aesthetic appeal. Another important consideration is the energy efficiency gained through the use of aluminum, especially in applications aimed at reducing the carbon footprint.

Aluminum plates are increasingly becoming a popular choice for various projects due to their cost-effectiveness and sustainability. With the global aluminum sheet market projected to grow significantly in the coming years, businesses are recognizing the value aluminum can bring. The lightweight nature of aluminum not only reduces shipping costs but also contributes to energy savings during manufacturing processes.

Tips for utilizing aluminum plates effectively include selecting the right alloy for your specific application, considering recycled aluminum to minimize environmental impact, and adopting modern production techniques. For instance, continuous casting processes enable efficient production of high-alloy aluminum, which can enhance the performance and longevity of the products.

Furthermore, aluminum's recyclability plays a crucial role in its sustainability credentials. Industries such as shipbuilding are beginning to integrate recycled aluminum to lower their ecological footprints. Embracing aluminum plates in your next project not only makes financial sense but also aligns with global sustainability goals. Ensure that you evaluate your materials carefully to take full advantage of the benefits aluminum can offer.

| Dimension | Benefit | Application | Cost Savings | Sustainability |

|---|---|---|---|---|

| Thickness: 1/8" | Lightweight yet strong | Automotive components | Reduced shipping costs | 100% recyclable |

| Thickness: 1/4" | Corrosion resistant | Architectural applications | Longer lifespan | Low carbon footprint |

| Thickness: 1/2" | Easy to machine | Aerospace components | Efficiency in production | Recyclable without quality loss |

| Thickness: 3/8" | Versatile in applications | Marine industry | Cost-efficient manufacturing | Sustainable resource |

When considering materials for a project, aluminum plates present distinct advantages over other options. In a comparative analysis, aluminum shines due to its lightweight nature and high strength-to-weight ratio. Unlike heavier materials such as steel, aluminum is easier to work with, making it a preferred choice in applications across aerospace, automotive, and construction industries. For instance, in bearing or valve manufacturing, aluminum's corrosion resistance and durability make it ideal for components that require longevity and low maintenance.

In terms of functionality, materials can be broadly categorized into inert and active types. Aluminum, being relatively inert, does not react readily with other substances, which is crucial in applications where exposure to harsh environments is expected. In contrast, more reactive materials like certain alloys can degrade faster, thus requiring more frequent replacements.

**Tip:** When selecting materials for your next project, consider the application requirements and environmental factors to determine if aluminum is the right choice.

Furthermore, the global market trends indicate a strong growth trajectory for aluminum products. By 2034, the painted aluminum composite market is projected to witness significant expansion, emphasizing aluminum's integral role within various industries. Investment in aluminum supply chains will likely yield high returns as industries increasingly shift towards lightweight and sustainable materials.

**Tip:** Stay updated on industry trends to leverage opportunities in aluminum innovation for your projects.

This chart illustrates the advantages of aluminum plates compared to other materials based on various factors such as weight, cost, corrosion resistance, and versatility. The data shows that aluminum plates offer significant benefits for construction and manufacturing projects.