In the fast-evolving field of materials, understanding Aluminum Plates is crucial. Recognized industry expert, Dr. Jane Smith, once stated, “The right Aluminum Plate can significantly enhance product performance.” This highlights the importance of selecting quality materials.

Aluminum Plates are versatile and widely used in various sectors. Their lightweight nature, coupled with durability, makes them popular. However, not all Aluminum Plates are created equal. Some lack the strength or corrosion resistance needed for specific applications. Choosing the right type can be a daunting task.

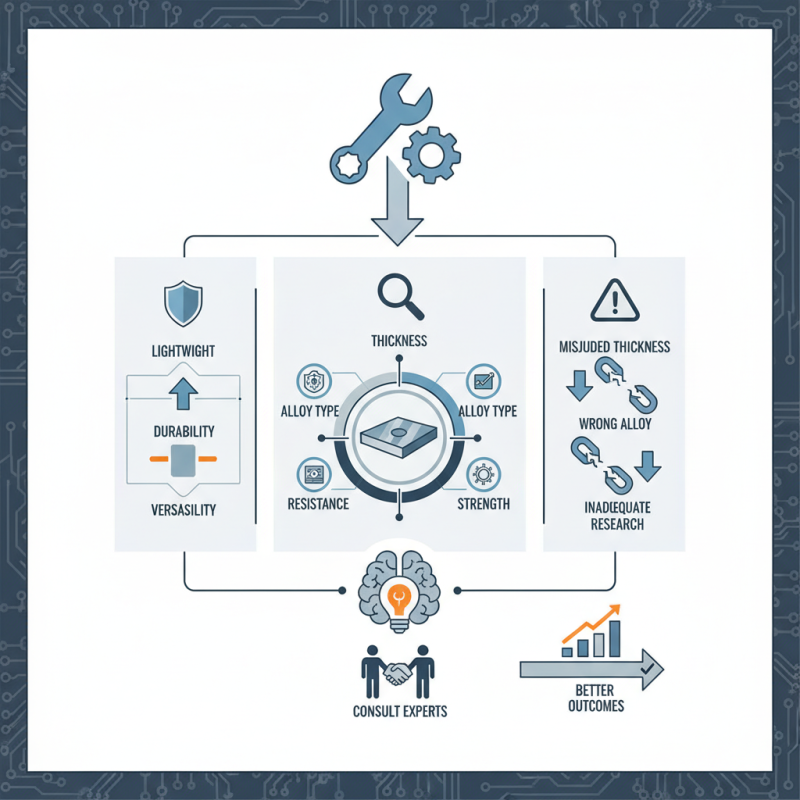

Beware of common pitfalls when selecting Aluminum Plates. Misjudging thickness or alloy composition can lead to failures. Inadequate research can result in costly mistakes. It is essential to delve deeper, recognize options, and consult experts for guidance. Understanding the nuances of Aluminum Plates will ultimately lead to better outcomes in projects.

Aluminum plates come in various types and specifications. Understanding these differences is essential for many applications. The most common types include 5052, 6061, and 7075. Each type differs in properties like strength, corrosion resistance, and workability.

Specifications also matter. Think about thickness, width, and length. Plates can range from very thin to over several inches thick. Different industries require specific sizes. For instance, aircraft manufacturers often use thinner, lightweight plates. In contrast, construction might need thick, durable options.

Keep in mind, not all aluminum plates are created equal. Some may have surface imperfections or inconsistencies in thickness. These issues might affect your project's outcome. Reflect on these details before making a choice. The right aluminum plate can lead to success, but a poor choice may result in setbacks.

When choosing aluminum plates, several key factors come into play. The thickness of the plate is critical. Common thicknesses range from 0.016 to 0.500 inches. Reports indicate that as the thickness increases, so does the weight and strength. For structural applications, plates need to meet certain strength criteria. Many industry standards require specific yield strengths ranging from 40 ksi to 70 ksi.

Another factor is the alloy type. Different alloys offer varying characteristics such as corrosion resistance or weldability. The 5000 series is known for its marine applications due to excellent corrosion resistance. According to market analysis, these alloys can reduce maintenance costs by up to 30% in maritime settings.

Surface finish is also important. A smooth finish can improve aesthetics and provide better bonding surfaces, while a rougher finish may enhance fatigue resistance in certain applications. The choice often depends on the final application. Many users overlook the impact of surface treatments, leading to potential failures in performance. The decision should involve a thorough evaluation of project requirements and conditions.

Aluminum plates are becoming vital across multiple sectors. These materials are lightweight, durable, and resistant to corrosion. This makes them ideal for construction, automotive, and aerospace applications. In construction, aluminum plates are often used for cladding and roofing. Their ability to withstand harsh weather makes them a preferred choice.

In the automotive industry, manufacturers use aluminum plates to reduce vehicle weight. Lighter cars save fuel and improve performance. However, not all aluminum alloys are equal. Choosing the right one can be challenging. Every alloy has unique properties. It requires careful consideration based on the application.

The aerospace sector relies heavily on aluminum plates. They provide strength without adding excess weight. Airplanes can use these plates in various components. This also means there's a need for precision in manufacturing. Any small mistake can lead to significant issues. The balance between quality and cost remains a constant challenge in this field.

When comparing aluminum plate suppliers, quality and pricing are key factors. Understanding these aspects can greatly influence your decision. High-quality aluminum plates often come with superior durability and strength. They are essential for industries like construction and aerospace. However, pricing can vary significantly among suppliers, and this is where some challenges arise.

Some suppliers may offer competitive prices but compromise on quality. This can lead to future issues, such as defects or increased maintenance costs. It’s crucial to balance your budget with quality requirements. Examining supplier reviews and asking for samples can provide insights. Don't rush this process. Take your time to evaluate your options carefully.

Check if the suppliers use advanced manufacturing techniques. This can enhance the final product's quality. Additionally, consider their customer service and support. A responsive supplier can make a difference during critical projects. Assessing these details will provide clearer pathways to making an informed choice. Sometimes, finding the right supplier feels overwhelming, but a methodical approach can simplify your search.

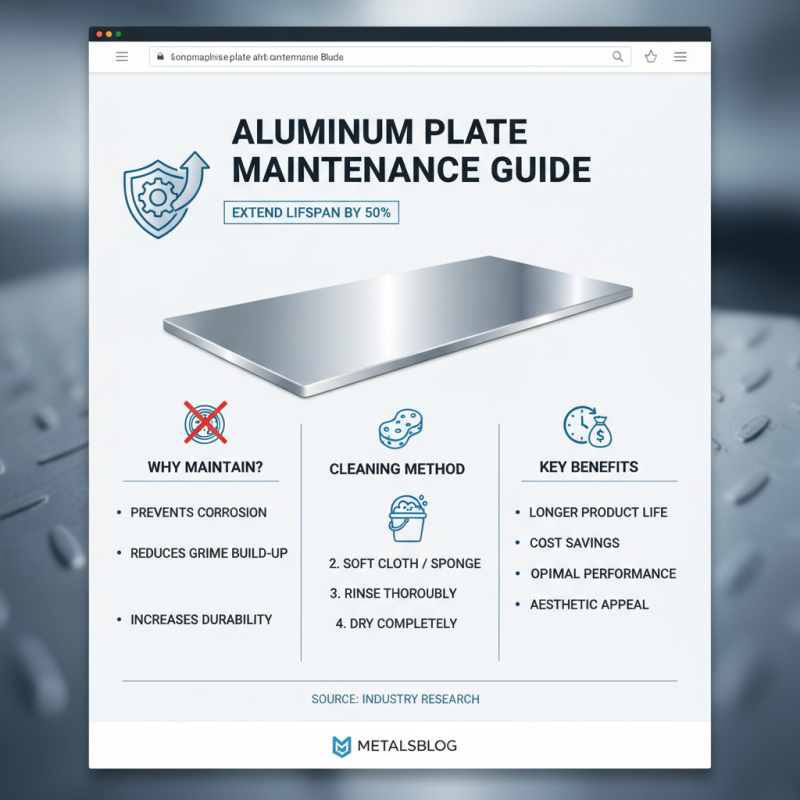

Aluminum plates are widely used in various industries due to their lightweight and durability. However, to maximize their lifespan, proper maintenance is key. Regular cleaning is essential. Dirt and grime can accumulate, leading to corrosion over time. A simple solution is using mild soap and water. Research shows that regular maintenance can extend aluminum plate life by up to 50%.

Storing aluminum plates correctly is also vital. They should be kept in a dry environment away from direct sunlight. Exposure to moisture and UV light can degrade the material. It’s important to check for signs of wear, like scratches or dents. Ignoring minor damages can lead to larger issues in the future. Keeping an inventory of the condition is often overlooked but crucial for effective maintenance.

Another often forgotten aspect is lubricating moving parts if applicable. This reduces friction and wear. A study indicated that proper lubrication can enhance performance and longevity by around 30%. Regular inspections and proactive care can prevent major repairs. Making these small adjustments leads to significant benefits over time. Neglecting these points may result in unnecessary expenses down the road.